Completed FTPs - RIC Americas

Path Planner Optimization and Planning Request Adapter

Champion: IDEXX Laboratories

Additional Sponsor: SwRI Internal Research Program

Completion Date: May 2014 (Completed)

Abstract: Optimizing industrial pick-and-place applications often involves minimizing the cycle time required for each move. While the ROS motion planning framework, MoveIt!, is quick to find collision-free paths to a goal point, the default configuration does not provide a minimum cycle-time solution. The objectives of this Focused Technical Project included:

Create a path planning capability which provides paths useful for industrial robot tasks

Generate paths that are asymptotically optimal (more computation time will yield an increasingly optimal solution)

Make tuning parameters accessible and explicit

Document these improvements so they can benefit the ROS community

Create an example planning request adapter that smooths planner output trajectories (also to improve cycle time) and more generally to enable anyone to compose a planning request adapter for MoveIt!

Generate a tutorial for planning request adapters

Outcomes:

Video (above, click to play)

Slides (includes instructions for installation from source)

Tutorial on Developing a Planning Request Adapter

Robotic Blending, Milestone 1

Completion Date: July 2014 (Completed)

Abstract: CNC mills often leave tool marks or surface discontinuities in metal parts that must be blended out by hand during post-processing. The blending operation is ergonomically hazardous for humans. A robotic blending solution is under development that will:

Use a robot-mounted course 3D-scanner to identify flat, reachable, blendable surfaces on each unique work piece

Plan blending process paths to sand the surfaces

Develop a GUI to make the workflow accessible to a non-programmer on the factory floor

Demonstrate the ability to scan and plan for a real aerospace work piece. Note that robot motion is limited to scanning for milestone 1.

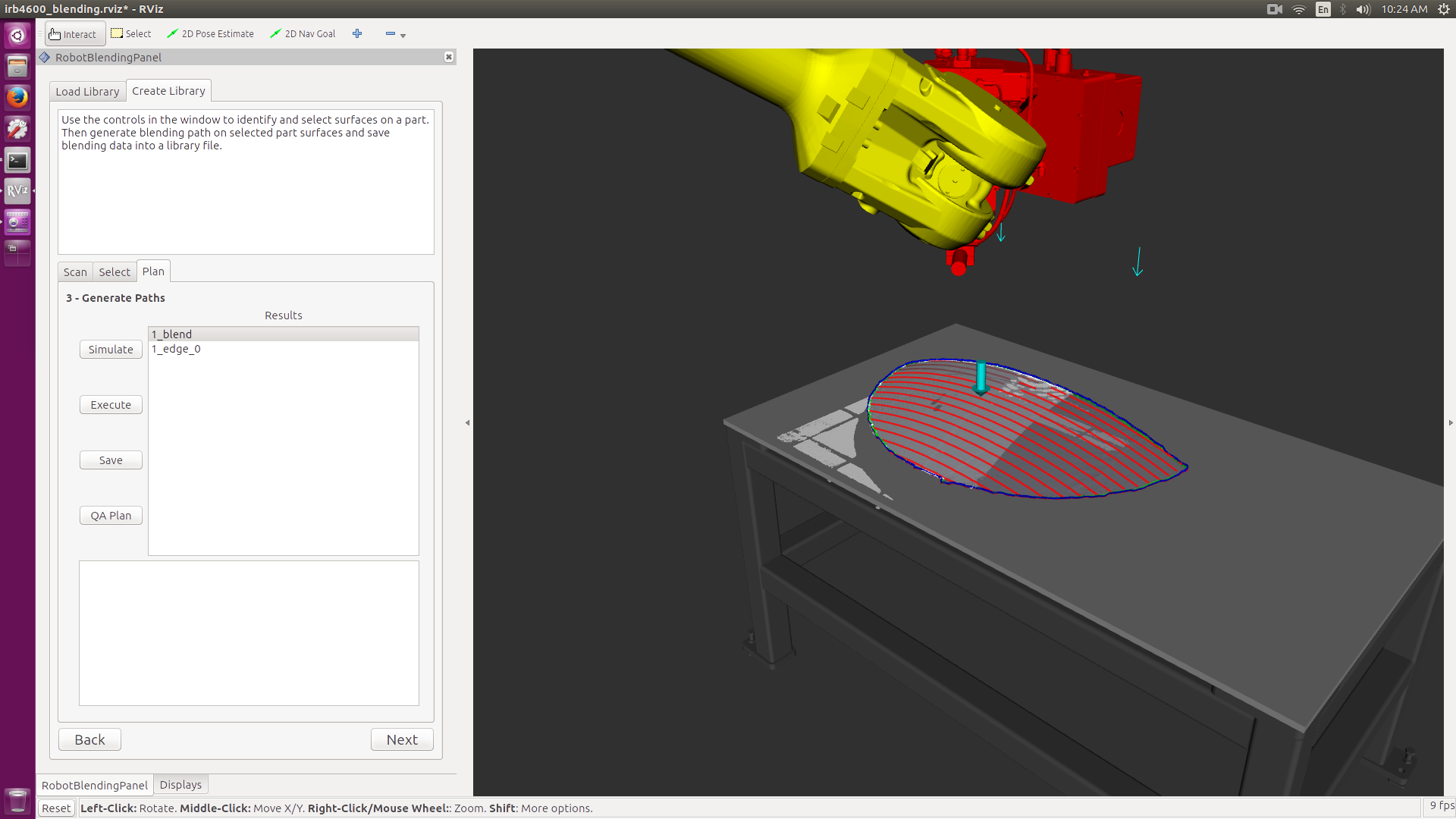

Robotic Blending Milestone 1: Rough scan (left), blend/sand (right). Images are notional - work is ongoing. Note that Milestone 2 will introduce laser line scanning for better accuracy and surface roughness automatic inspection.

Robotic Routing

Champion: Textron

Additional Sponsors: CNRC, SwRI

Completion Date: March 2015 (Completed)

Abstract: Cessna has thousands of legacy Hand Route Tools (HRT) with no corresponding 3-D CAD data. Their production robotic routing cell is capable of relieving the ergonomic burden of hand-routing, but it is time consuming to teach each unique tool. Cessna is collaborating with CNRC and SwRI to develop and deploy a ROS-I solution to accelerate robot path planning for HRT paths. The solution uses a FARO coordinate measurement arm to quickly acquire the HRT geometery, then the new Descartes path planner (refer to page 7) creates a robot joint trajectory, and finally the trajectory is converted to a permanent KRL program that can be played back at any time in the future.

Robotic Blending, Milestone 2

Champion: Spirit AeroSystems

Additional Sponsors: SwRI

Completion Date: March 2015

Abstract: This is a continuation of the milestone 1 project. It will added the following capabilities:

Automatically generate collision free robot joint trajectories to collect high resolution laser line scanner data from the user-designated regions on the work piece

Automatically analyze the high resolution scan data and colorize and display the surface data according to the quality metric

Test and improve the software to work with work piece submissions from three sponsors

Demonstrate the end-to-end robotic scanning and blending process with real hardware

Robotic Blending Milestone 3

Champion: Caterpillar and Boeing

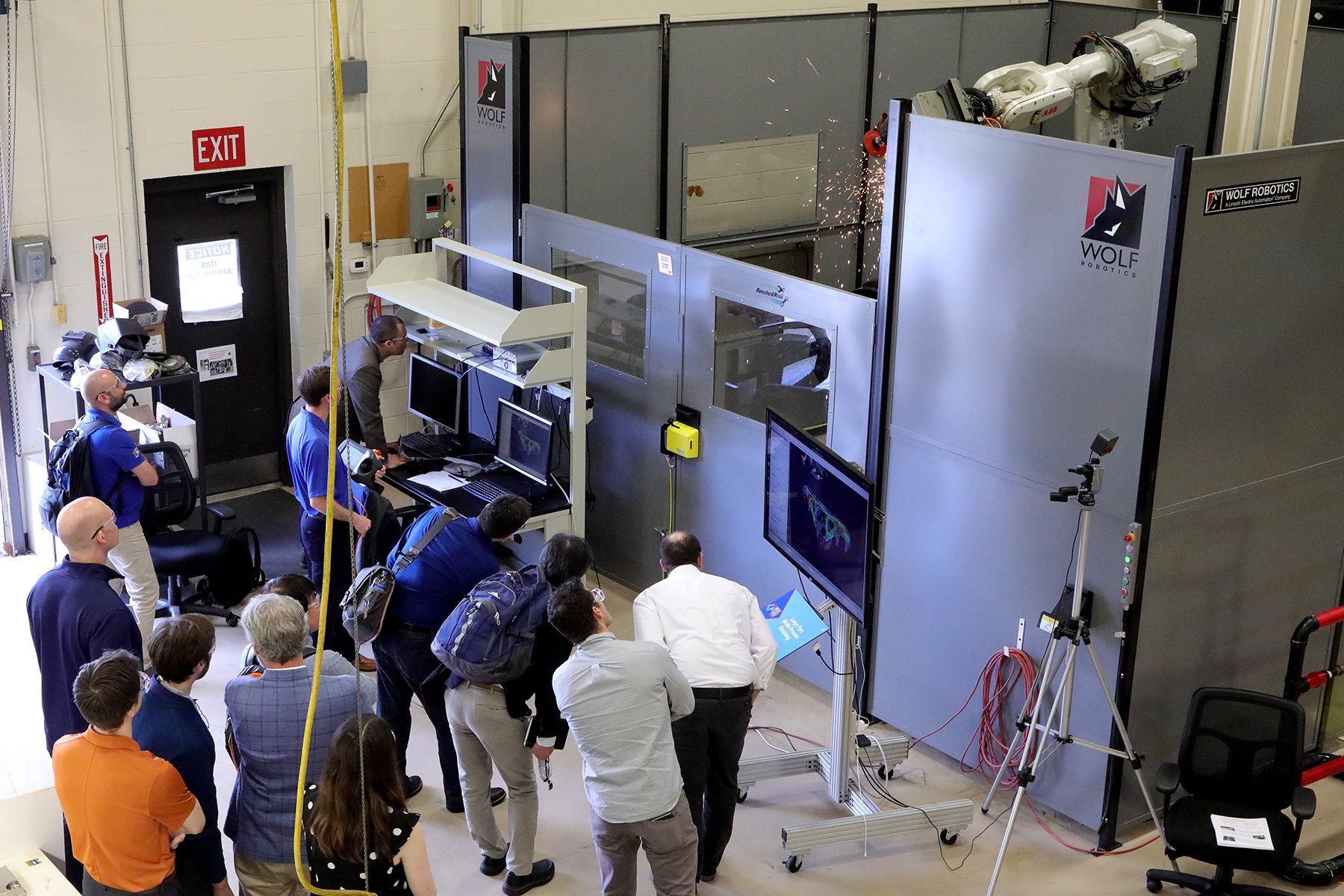

Performers: SwRI and Wolf Robotics (Lincoln Electric Automation)

Completed: July 2015.

Abstract: Many metal fabrication processes including casting, machining, and welding produce parts with surface finish defects (i.e. pitting, mill-lines, or weld spatter). Many processes are available to remove these defects including manual sanding, grinding, bead blasting, or vibratory polishing. In high volume applications, manual processing can lead to ergonomic or safety hazards. Also, inconsistency from operator to operator can lead to variations in product quality, excessive use of consumables, or inefficiencies. A solution is desired that combines the flexibility of a manual process with the repeatability and safety of the robotic system.

The objectives of the Milestone 3 FTP include:

Technology transfer from SwRI to a leading system integrator, who is capable of commercializing the Robotic Blending capability.

Human interface improvements for ease of use and process flexibility.

Micro-scanner data acquisition acceleration for shorter cycle times.

Testing and documentation to enable successful reproduction of results.

Results

New robot support

ABB 2400, 2600, 6600

Custom ABB driver includes process control

HMI

Full process integration (no consoles)

Adjustable process parameter menus (QA and Blending)

Streamlined GUI for operators

Simulated robot for previews

Keyence

Ability to change programs

High-Speed mode (1000Hz)

Knowledge Transfer

Demos at SwRI, Boeing, and Caterpillar

Testing/Integration

Countless practical lessons and bug-fixes

Parts were blended on multiple robots in multiple states

CAD to ROS Milestone 1

Champion: Boeing

Performers: SwRI, TU Delft, TracLabs

Completed: November 2016.

Abstract: Milestone 1 Objectives

This project started with an internal project to create a URDF editor using QT widgets and leveraging an RViz plug-in as the 3D visualization environment (refer to Figure 2). Milestone 1 software development began with this preliminary URDF editor as a starting point. More information and current repository may be found at: https://github.com/ros-industrial-consortium/CAD-to-ROS

Robotic Blending Milestone 4

Champion: Caterpillar & GKN Aerospace

Performers: SwRI, Wolf Robotics (Lincoln Electric Automation), 3M

Completed: September 2017.

Abstract: Starting in earnest at the beginning of 2017, Milestone 4 (M4) sought to further the functionality of the technology to incorporate functionality that was of interest to the participating members. These members, 3M, Caterpillar, and GKN Aerospace, Wolf Robotics, along with the SwRI development team set forth to realize a set of objectives:

Closed-loop inspection and retouch: Integrating the process planning and quality assurance steps so that parts are finished with a closed, sensor-driven loop.

More Robust Surface Segmentation: Improving the surface segmentation and planning algorithms to accommodate more complex surfaces found on real parts (continuous surfaces with radius of curvature above a 50 mm threshold)

Blending Process Refinement: Improving the quality of the blending process to produce surface finishes that meet engineering requirements.

Edge Processing: Processing/chamfering simple 2.5D edges that occur where two surfaces meet.

Technology Transfer: Meetings and demonstrations and sponsor sites to support knowledge sharing among project participants and performers.

Integration and Testing: Integration and testing to support demonstrations.

The intent of the demonstration was to review the capability as-developed relative to the processing of provided Caterpillar production parts. Performance was tracked to a provided success criteria that tied to performance metrics that were relevant to the target application. Overall the performance met the stated requirements and interest in follow on work was stated. A report and video were published.

FTP Topics that are Brewing - RIC Americas

ROS Workbench: Non-programming interface for environment configuration, setting up Scan-N-Plan type systems.

GPU-Accelerated Collision Checking: Plan collision-free paths in real time with hardware-accelerated collision checking.

Heavy Helper: Create a human-robot collaboration demo for teleoperated material handling where parts exceed weight limit for one-man-lift. Application: CNC machine tending.

Robotic CAM-style Planning: A continuation from Milestone 1. It will close the loop to achieve a target accuracy of +/- 0.05" for path following for light machining.

OPC-UA DDS Bridge: Interoperability bridge to enable more efficient DDS-OPC-UA interactions.

Inquires

For more information about any of these topics, please contact Matt Robinson