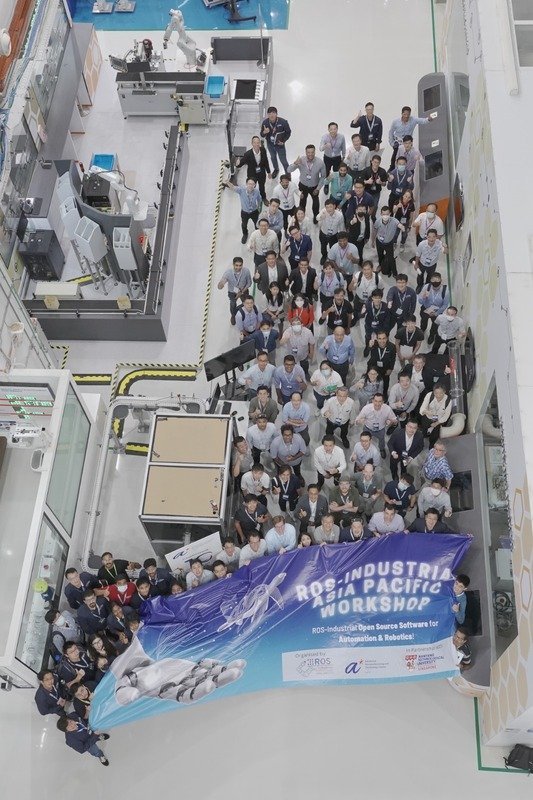

This year’s summit featured an impressive agenda packed with expert talks, hands-on masterclasses, and an engaging tech marketplace, all designed to highlight how AI is transforming robotics across industries, especially in manufacturing, logistics, and physical security.

Day 1 Highlights

The first day of the summit opened with a series of insightful presentations by leaders from major organizations in the AI and robotics space.

Amazon Web Services (AWS) set the tone with a talk titled "AI and Robotics-Driven Innovations for Manufacturing Excellence." Presented by Mirela Juravle, Data and AI Specialist Lead at AWS, the session showcased how robotics and AI are being leveraged to support digital transformation efforts toward achieving "lights-out" manufacturing, a concept where factories operate autonomously without human intervention. AWS shared insights on the benefits of cloud services in scaling robotic operations and optimizing workflows for increased efficiency in manufacturing.

Next, Mitsuharu Sonehara, Manager at IHI Corporation’s Technology Planning Department, presented on IHI's vision of advancing robotics and automation within logistics. Titled "From Deep Sea to Deep Space," his talk explored IHI's work in using robotics for high-stakes applications, from underwater operations to outer space logistics. He detailed the challenges and opportunities in these extreme environments and highlighted how AI and robotics can revolutionize logistics operations of the future.

Swarooph Nirmal Seshadri, Chief Technology Officer at Kabam Robotics, shared insights on the transformation of physical security through robotics, intelligence, and connectivity. His session explored how AI-driven robots are becoming crucial in the security industry, enabling smarter monitoring, data gathering, and response systems that are safer and more efficient.

Dr. Dikai Liu, a solution architect from NVIDIA, followed with an exciting presentation on NVIDIA’s suite of services, which facilitates the acceleration of robotics and AI from simulation to real-world deployment. NVIDIA’s tools and platforms empower developers to simulate complex environments and rapidly prototype AI algorithms for robotics, ultimately shortening the timeline from concept to deployment.

An important announcement on ROS2 compatibility came from Mr. Steven Chong, Senior Business Development Manager at Mitsubishi Electric Asia. He announced the release of a ROS2 driver for the MELFA robot, enabling broader integration with the ROS ecosystem. This advancement allows Mitsubishi Electric’s industrial robots to seamlessly integrate with ROS2, opening up new possibilities for automation in various industries. More details can be found on the ROS-Industrial blog here.

Wrapping up the first day’s talks, Dr. Yang Geng, Assistant Director at IMDA, presented on "Embodied AI as the Next Leap in GenAI." He described how embodied AI, which focuses on giving AI systems a physical presence, can revolutionize industries, from customer service robots to healthcare assistants, by enhancing interactions and adaptability through AI.

Day 2 Highlights

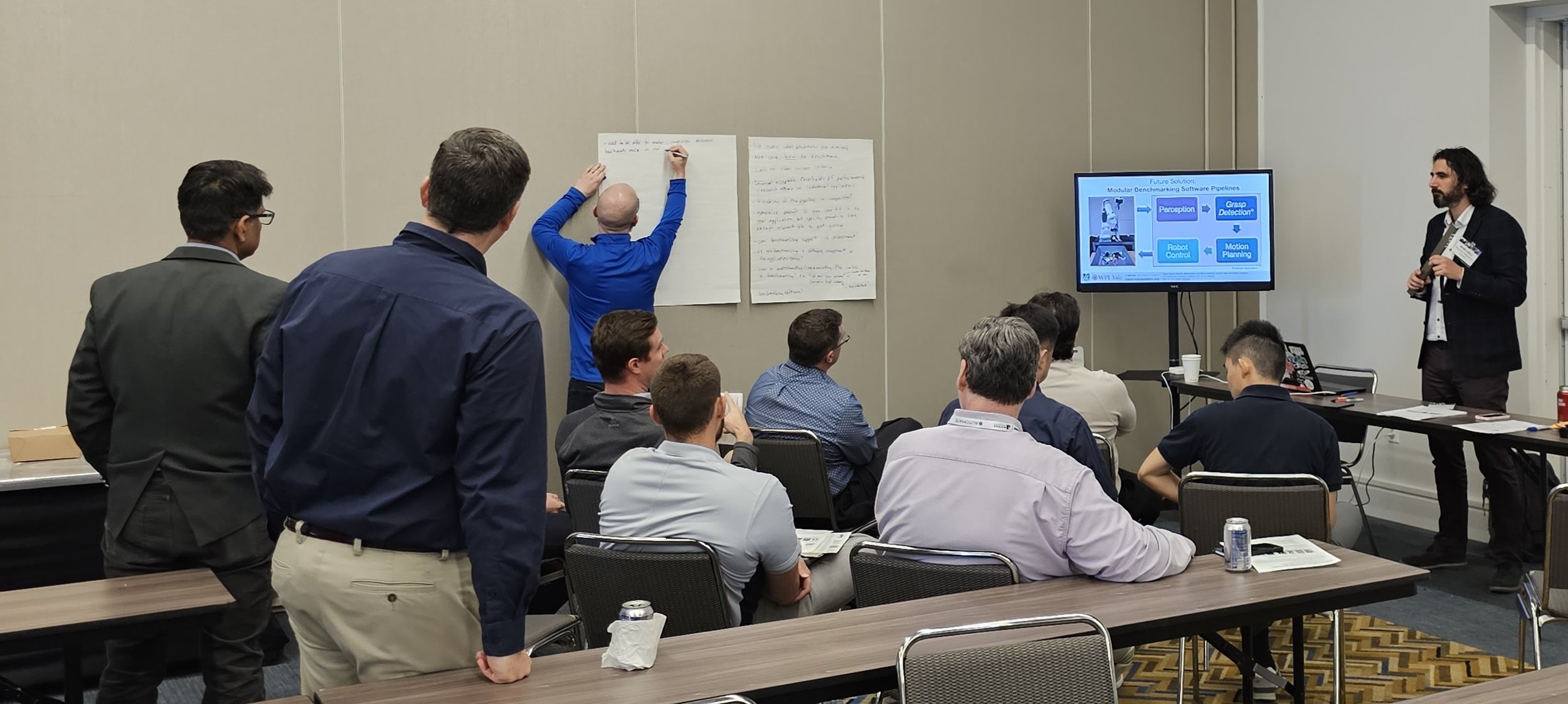

The second day of the summit was equally informative, beginning with a presentation by Matt Robinson, Consortium Manager at ROS-Industrial Consortium America. He discussed the collective global effort to standardize ROS2 drivers, aiming to establish ROS2 as the default industrial standard for robotics software. Robinson emphasized the benefits of this standardization for interoperability and efficiency in automation.

Following Robinson, Vishnuprasad Prachandabhanu, Consortium Manager of ROS-Industrial Consortium Europe, shared ongoing efforts to implement ROS2 across various applications. He highlighted a substantial EU-backed initiative with a €60 million funding commitment toward developing AI for robotics across Europe, signifying a significant investment in the advancement of open-source robotics.

Mr. Eugene Goh of JM Vistec presented next, offering insights on the integration of vision systems in robotics. His talk emphasized how JM Vistec enables robots to "see," enhancing precision and capability in industrial tasks, from quality inspection to object recognition.

Concluding the speaker sessions, Dr. Kenneth Kwok from IHPC shared cutting-edge research on enabling human-robot collaboration, powered by AI. His session emphasized the importance of human-centered AI in creating safe, efficient, and collaborative environments where robots can work alongside humans in factories, warehouses, and more.

Masterclass Lineup

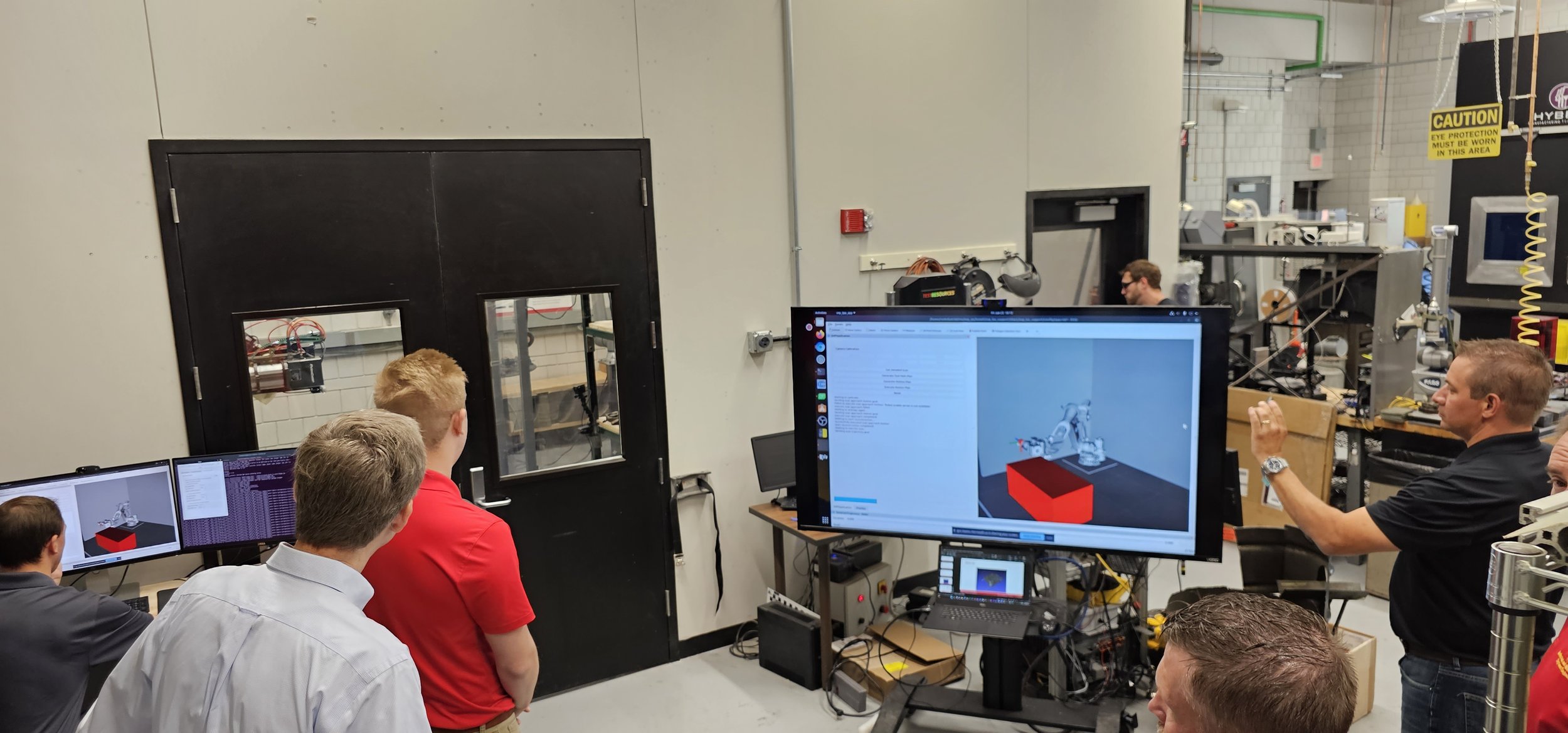

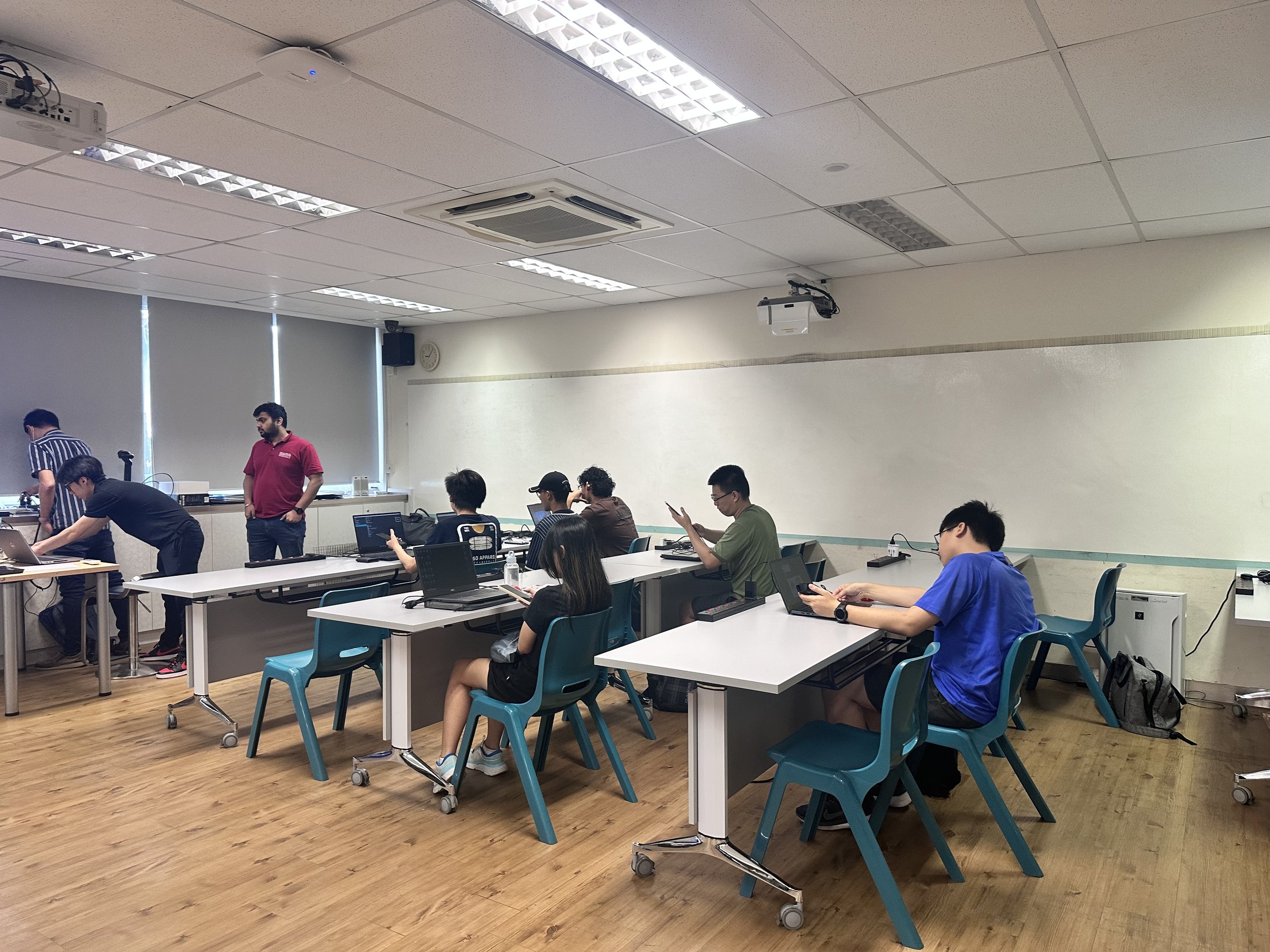

Participants then moved to the masterclass sessions, which provided hands-on learning experiences across various aspects of AI and robotics. Each session was designed to deepen the practical knowledge and technical skills required for integrating AI with robotics.

Empowering Innovations with MELSOFT: Led by Mr. Liu Muyao, Software Application Engineer from Mitsubishi Electric Asia, this session focused on MELSOFT, Mitsubishi's integrated software environment, which enhances the control and flexibility of industrial robots.

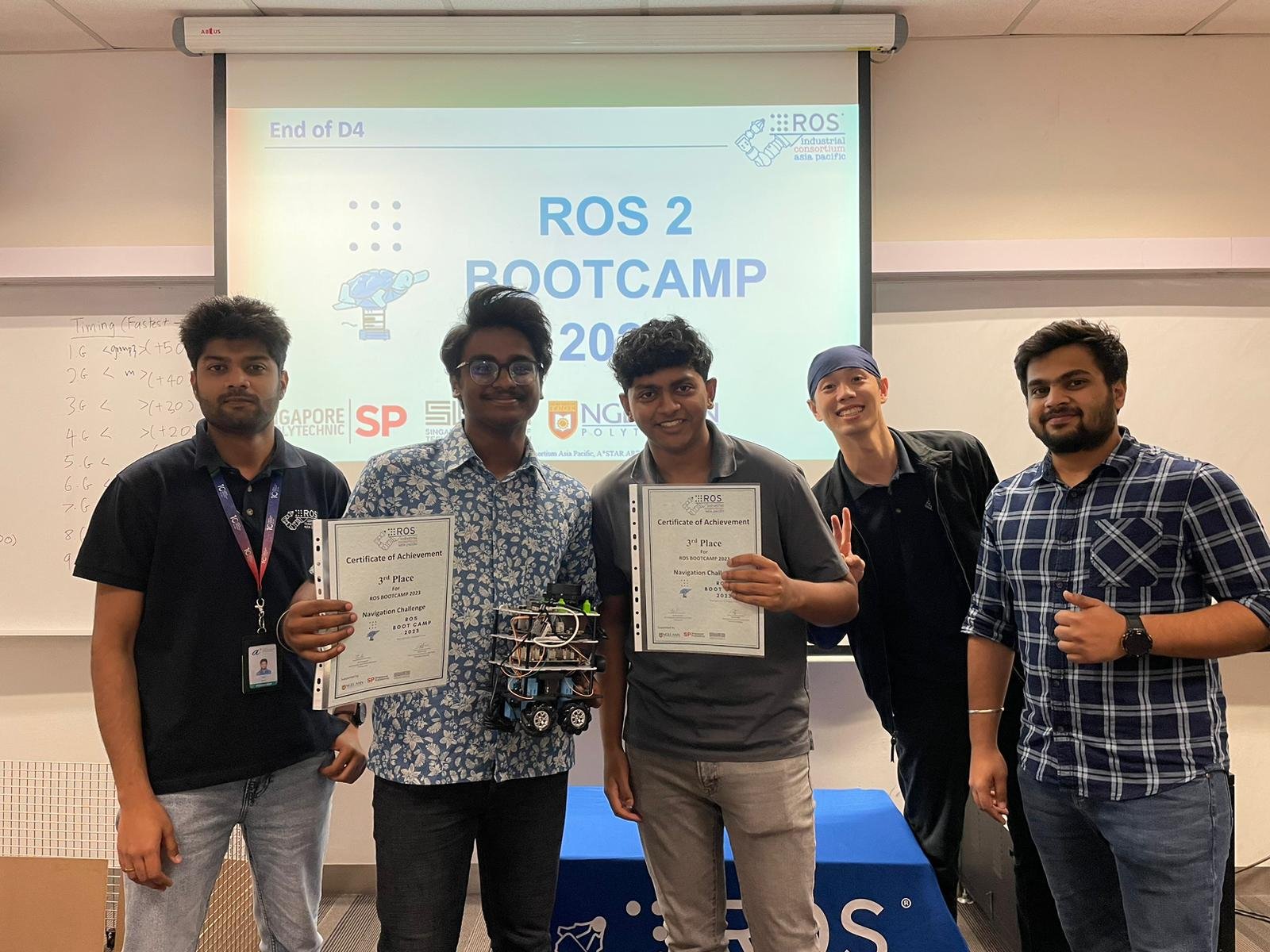

Introduction to Reinforcement Learning for Robot Arm Manipulation: Hosted by Mr. Shalman Khan, Mr. Santosh Balaji, and Ms. Mercedes Ramesh from ROS-Industrial Consortium Asia Pacific, this session introduced reinforcement learning principles, showing participants how to apply these techniques to control robotic arms more effectively.

Introduction to Deep Learning with YOLO and ROS: Dr. Carlos Acosta, Robotics Specialist at Singapore Polytechnic, led a session on utilizing YOLO (You Only Look Once) with ROS for object detection. The masterclass offered participants a foundation in integrating deep learning algorithms with ROS to enhance robotic vision applications.

Introduction to Fleet Management with Open-RMF: This session, led by Dr. Ricardo Tellez, CEO of The Construct, demonstrated the Open-RMF (Robot Management Framework) for multi-robot fleet management. Participants learned how to manage multiple robots collaboratively, a critical capability for applications in large facilities like hospitals and factories.

Tech Marketplace Highlights

The tech marketplace featured a diverse array of participants, including Megazo, Kabam Robotics, IHPC, Parasoft, and Pepperl+Fuchs. Each company showcased their latest innovations, giving attendees a firsthand look at cutting-edge robotics solutions and AI-driven technologies designed to tackle challenges in industries like manufacturing, logistics, and safety. The marketplace provided a vibrant space for networking, collaboration, and discovering new tools that could redefine industrial automation.

RIC-AP Annual Summit 2024 also announce 2025 exciting event as we welcome the largest ROS Conference, ROSCon 2025 to Singapore. This would be the first time ROSCon will be hosted in Singapore

Finally, on behalf of everyone at ROS-Industrial Consortium Asia Pacific, we would like to thank all participants and delegates for their enthusiasm and we look forward to RIC-AP Annual summit 2025.

To sign up for our upcoming events, register your interest via this link: [https://form.gov.sg/672480d8116743c2ed31c690]