Description

Background

ROS, an open-source project, provides a common framework for robotics applications. ROS is heavily utilized by the research community for service robotics applications, but its technology can be applied to other application areas, including industrial robotics. ROS capabilities, such as advanced perception and path/grasp planning, can enable manufacturing robotic applications that were previously technically infeasible or cost prohibitive.

ROS-I Founder Shaun Edwards with an Early Industrial Robot Application

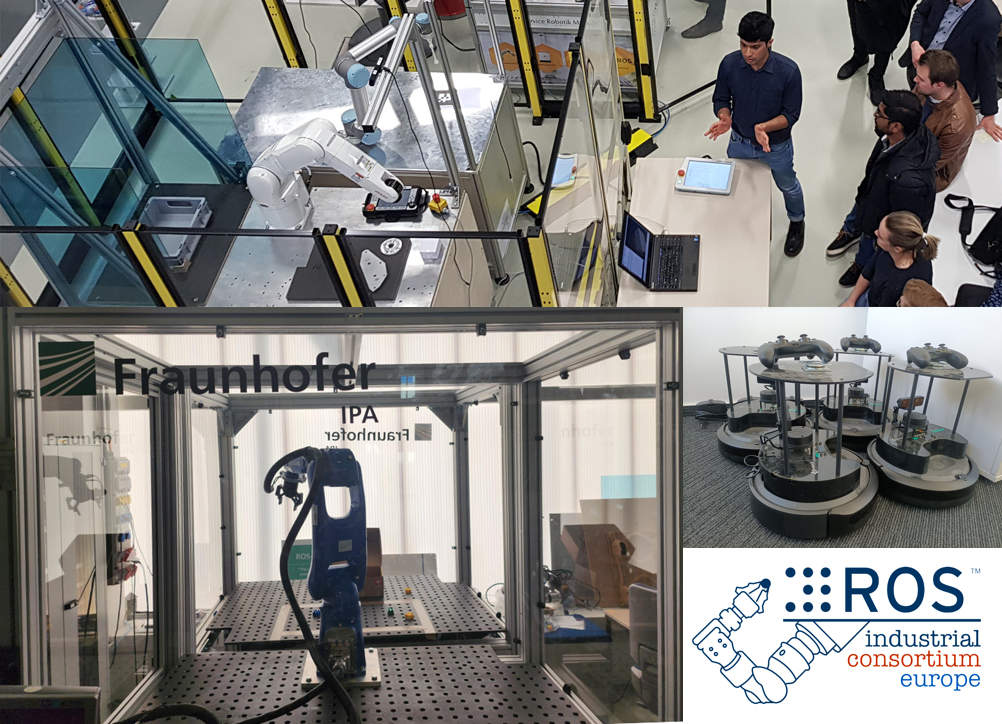

ROS-Industrial

ROS-Industrial is an open-source project that extends the advanced capabilities of ROS to manufacturing automation and robotics. The ROS-Industrial repository includes interfaces for common industrial manipulators, grippers, sensors, and device networks. It also provides software libraries for automatic 2D/3D sensor calibration, process path/motion planning, applications like Scan-N-Plan, developer tools like the Qt Creator ROS Plugin, and training curriculum that is specific to the needs of manufacturers. ROS-I is supported by an international Consortium of industry and research members. ROS-Industrial:

- Provides a one-stop location for manufacturing-related ROS software.

- Striving towards software robustness and reliability that meets the needs of industrial applications.

- Combines the relative strengths of ROS and existing technology, combining ROS high-level functionality with the low-level reliability and safety of an industrial robot controller, as opposed to replacing any one technology entirely.

- Stimulates the development of hardware-agnostic software by standardizing interfaces.

- Provides an "easy" path to apply cutting-edge research to industrial applications by using a common ROS architecture.

- Provides simple, easy-to-use, well-documented application programming interfaces.

ROS Industrial Benefits

The ROS-Industrial stack:

Leverages powerful functionality within ROS:

- Custom inverse kinematics for manipulators, including solutions for manipulators with greater than six degrees-of-freedom.

- Advanced 2-D (image) and 3-D (point cloud) perception.

- Rich toolset for development, simulation, and visualization.

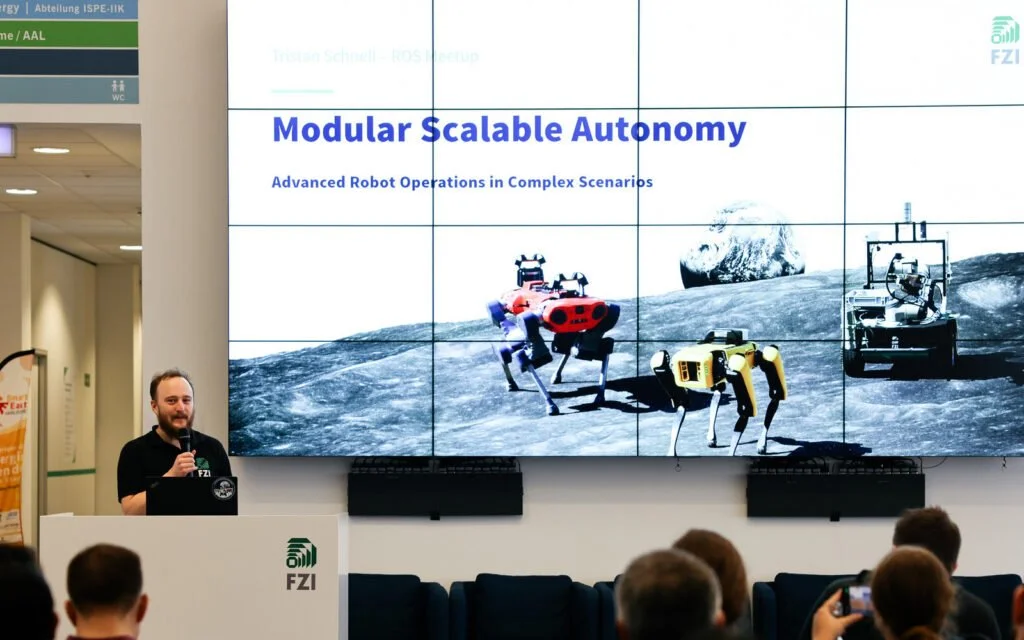

Enables new applications

- Unstructured applications that include advanced perception for identifying robot work pieces as opposed to hard tooling.

- Scan-N-Plan algorithms based upon advanced perception and just-in-time planning as opposed to simply replaying taught paths.

- Model-based approaches that permit automated programming for thousands of unique CAD parts.

Simplifies robot programming to the task level

- Eliminates path planning and teaching. Collision-free, optimal paths are automatically calculated given tool path waypoints.

- Applying abstract programming principles to similar tasks (useful in low-volume applications or with slight variations in work pieces).

Reduces costs

- Open-source software used and supported by the community. Preferred open-source licenses (i.e., BSD and Apache 2.0 licenses) allow commercial use without restrictions.

- Reducing manufacturer "lock-in" by standardizing robot and sensor interfaces across many industrial platforms.

Open-Source Resources

- ROS-Industrial Open-Source Software Web page provides installation instructions and tutorials for new users.

- The ROS-Industrial Consortium web page has information for partners who would like to be involved in the continued development of ROS-Industrial. The page also has information about the specific benefits enjoyed by consortium members.

- The ROS Software wiki page provides detailed information on the ROS software on which ROS-Industrial is based.

- ROS-Industrial is released under the business-friendly BSD and Apache 2.0 licenses.