ROS-Industrial Focused Technical Project Robotic Blending Milestone 5 Launches

/The ROS-Industrial Consortium, championed by the Steel Founders’ Society of America (SFSA), has launched the Focused Technical Project (FTP) Robotic Blending Milestone 5. This builds on the prior Robotic Blending Milestone 4, which demonstrated high-mix material surface finishing and edge processing of arbitrarily shaped and contouring parts, largely targeting piece-parts to be welded.

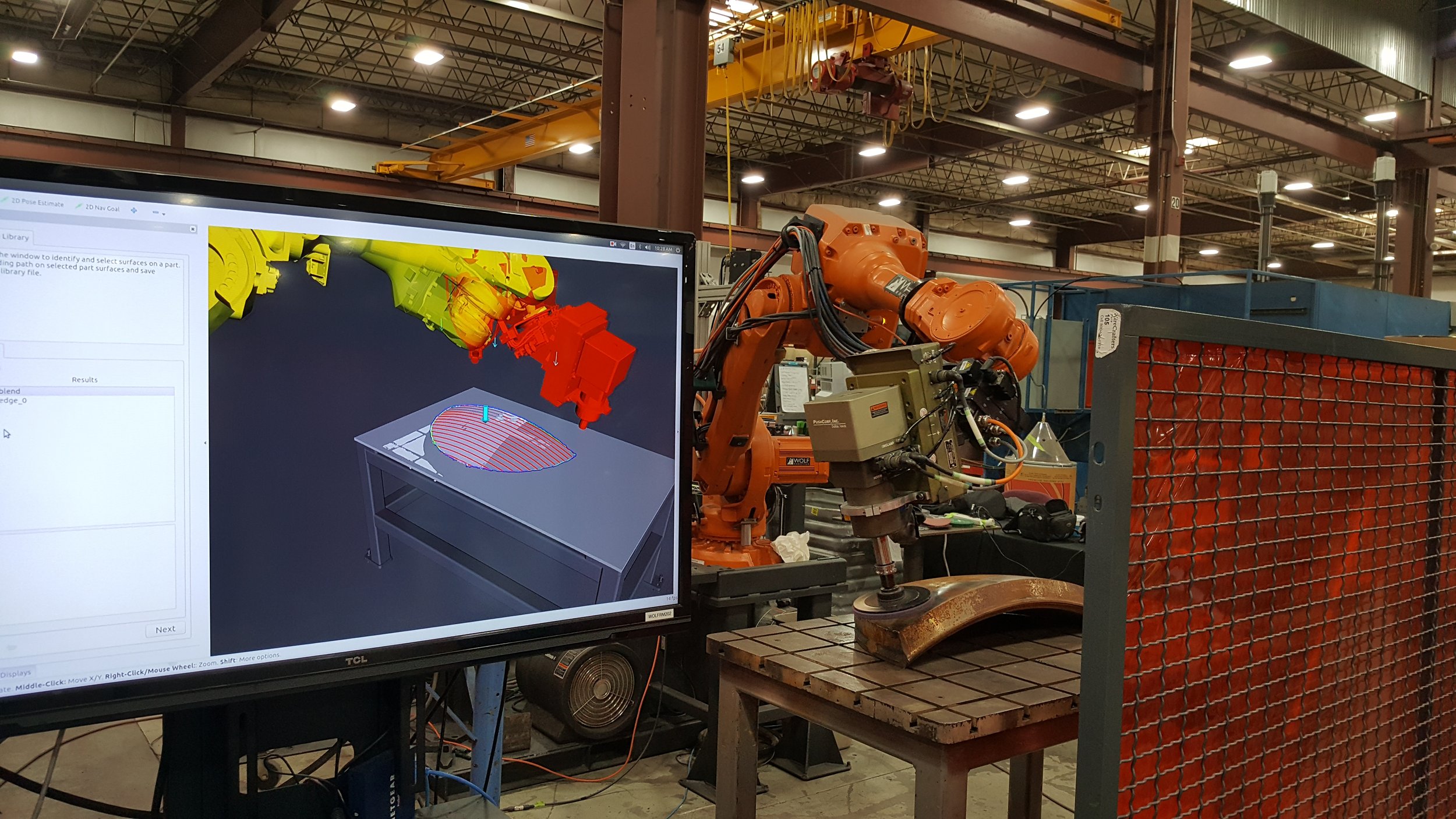

In this new milestone, launched in March, the key goal is to place a working system at an SFSA member foundry site, and enable that end-user to leverage the CAD free, entirely perception-driven system to remove unwanted surface features due to casting pour process and finish the total surface area for subsequent inspection and ship to the client.

To make this FTP a reality, a diverse team provided various forms of contribution to enable successful application development, core capability implementation, testing, and a pathway to replication for additional foundries. This team consists of champion SFSA, Southwest Research Institute (SwRI), Yaskawa America, PushCorp, Iowa State University (ISU), deployment foundry Fisher Cast Steel, and in-kind team members ARIS Technology and Edison Welding Institute.

As is the case in prior FTP efforts, there will be multiple integration events that enable cross-team collaboration and will leave functioning capability at partner sites. In this case with partner university ISU, which will integrate recently developed capability, host a collaborative integration event, while learning the blending framework. SFSA has a long history of working with ISU and a key milestone will be implementing into the Scan-N-Plan framework recently developed riser removal perception driven finishing that has been demonstrated in the ISU lab. The goals of this integration of the ISU capability are to leave a functioning Scan-N-Plan system in the ISU lab to enable them to implement and test capabilities developed with SFSA and enable more efficient transfer to end-user sites that may adopt the Robotic Blending capability in the future.

The project completes with an integration event at the SFSA member, Fisher Cast Steel, and demonstration of capability on production cast parts. The removal surface irregularities due to riser removal will be evaluated across the parts as well as overall surface finishing to support surface inspection processes where required. A summary of core repositories that were improved will be detailed and a highlight video and supporting documentation will be provided. In-kind partners will have the opportunity to support additional end-users to adopt the capability and make further refinements on top of the core developed capability.

The ROS-Industrial Consortium, in collaboration with SFSA and the development team look forward to furthering advanced robotics capability for industry and to provide a pathway for foundries to adopt intelligent automation for high mix casting environments.

Acknowledgement: This research is sponsored by the DLA-Troop Support, Philadelphia, PA and the Defense Logistics Agency Information Operations, J68, Research & Development, Ft. Belvoir, VA.

Disclaimer: The publication of this material does not constitute approval by the government of the findings or conclusion herein. Wide distribution or announcement of this material shall not be made without specific approval by the sponsoring government activity.