Scan-N-Plan™

Scan-N-Plan technologies are a suite of tools that enable real-time robot trajectory planning from 3-D scan data. Traditional industrial robot programming is performed using either online, teach-pendant programming or offline programming with a simulated version of the robot and work piece. The Scan-N-Plan approach overcomes limitations in traditional robot programming for applications that:

- Have highly variable part mixes such that hand programming is impractical

- Do not have CAD part models available

- Include flexible or deformable parts such that pre-programming is impossible

- Have part-to-part variability that is difficult to accommodate with static programming

- Require flexible part fixturing or no fixturing at all

These applications are representative of adaptable and flexible operations that respond dynamically to changes in part geometry or presentation — all with little or no human intervention. In addition, the dynamic nature of the trajectory generation permits real-time adaptation based on process feedback.

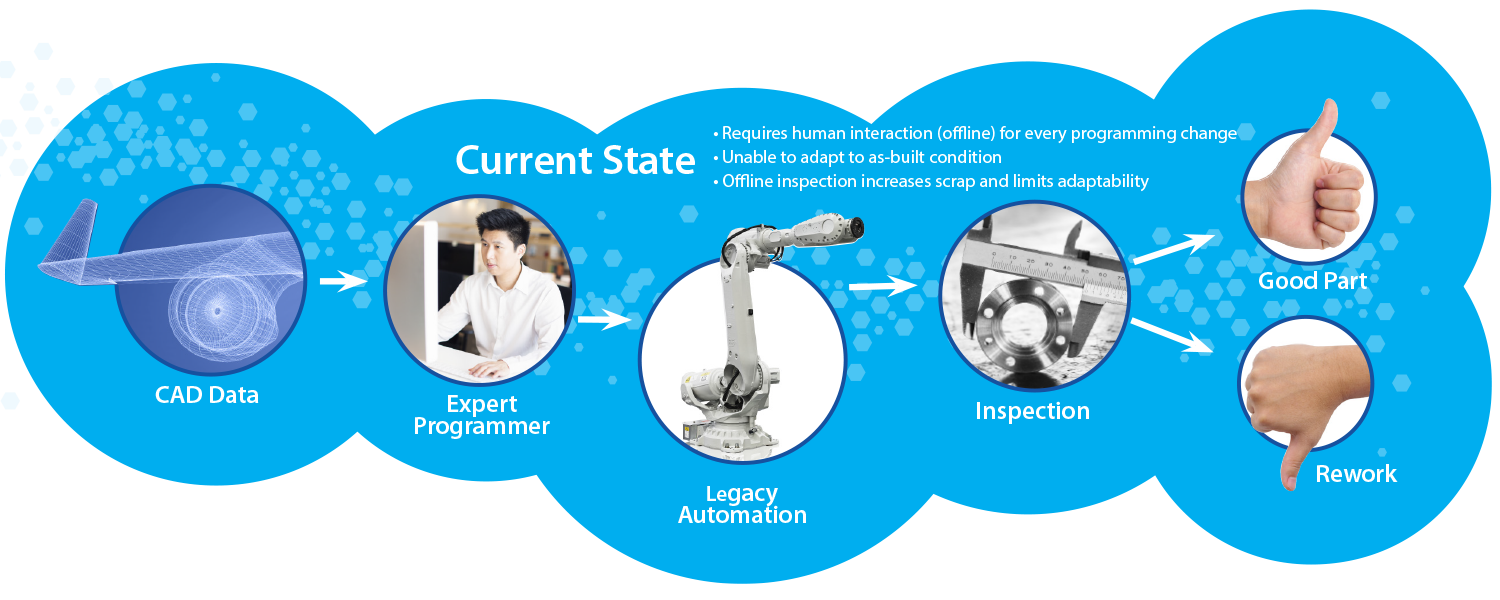

Traditional robot programming requires an expert-in-the-loop, which limits responsiveness to changes in the process:

Current or Traditional State of robotic application set up

The Scan-N-Plan approach leverages 3D scanning techniques to generate the part geometry and location in realtime, eliminating the human in the loop and enabling agility:

modular framework that enables on the fly autonomous trajectory generation and add-ons for greater capability

Scan-N-Plan can be generalized to many different processes such as painting, surface finishing, deburring, inspection, and others. The ROS-Industrial Consortium is currently developing the technique for surface blending (sanding) and it has previously been deployed in robotic paint applications.

Refer to the backside of this PDF for a summary of how the Robotic Blending Focused Technical Project Scan-N-Plan work has been leveraged.

For details around additional applications and deployment examples check out the below references:

- Spirit AeroSystems led ARM Institute project Collaborative Robotic Sanding: https://rosindustrial.org/news/2020/11/5/hbxkihnrz8hjiwidgr16m9hrd4faa7

- AFRL demos advanced robotics for aerospace manufacturing: https://www.wpafb.af.mil/News/Article-Display/Article/1516400/afrl-demos-advanced-robotics-for-aerospace-manufacturing/

- Enabling Adaptive Capabilities for Robotic Sanding: https://www.swri.org/industry/industrial-robotics-automation/blog/enabling-adaptive-capabilities-robotic-sanding-systems

- Mobile Autonomous Coating Application For Aircraft Sustainment https://arminstitute.org/project-highlight-mobile-autonomous-coating-application-for-aircraft-sustainment/

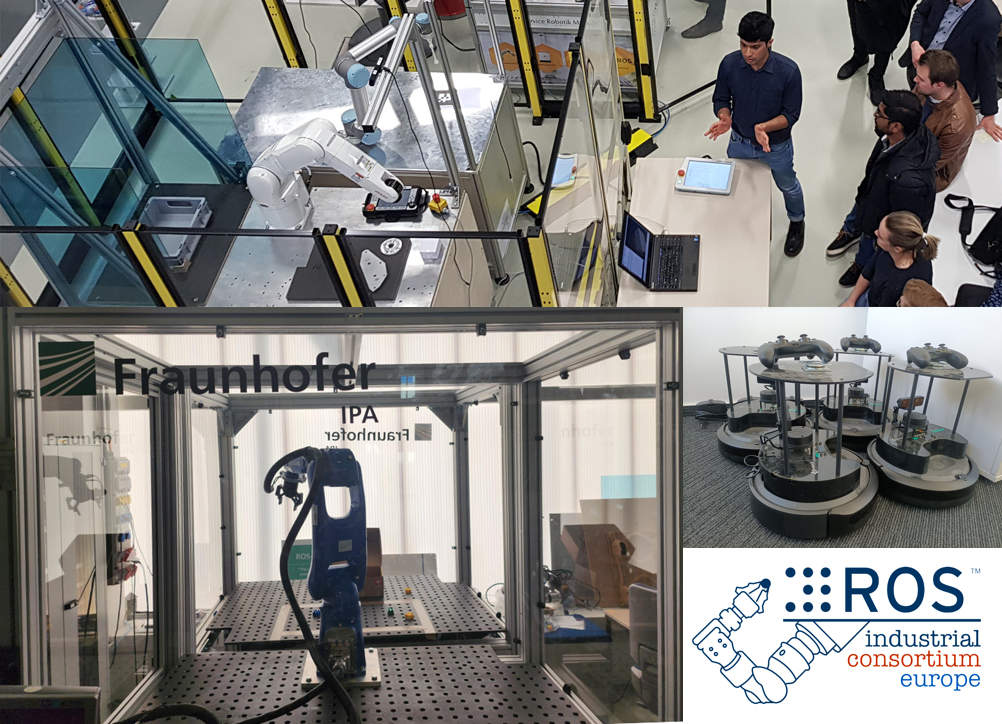

As part of EU-funded project ROSIN, Fraunhofer IPA made a Scan-N-Polish application together with ROS-Industrial Consortium member PILZ and showcased it on AUTOMATICA trade fair 2018 in Munich, Germany, as well as ROSCon and IROS 2018 in Madrid, Spain.

Download a printable PDF here