The Challenge: Transitioning Robotics R&D to the Factory Floor

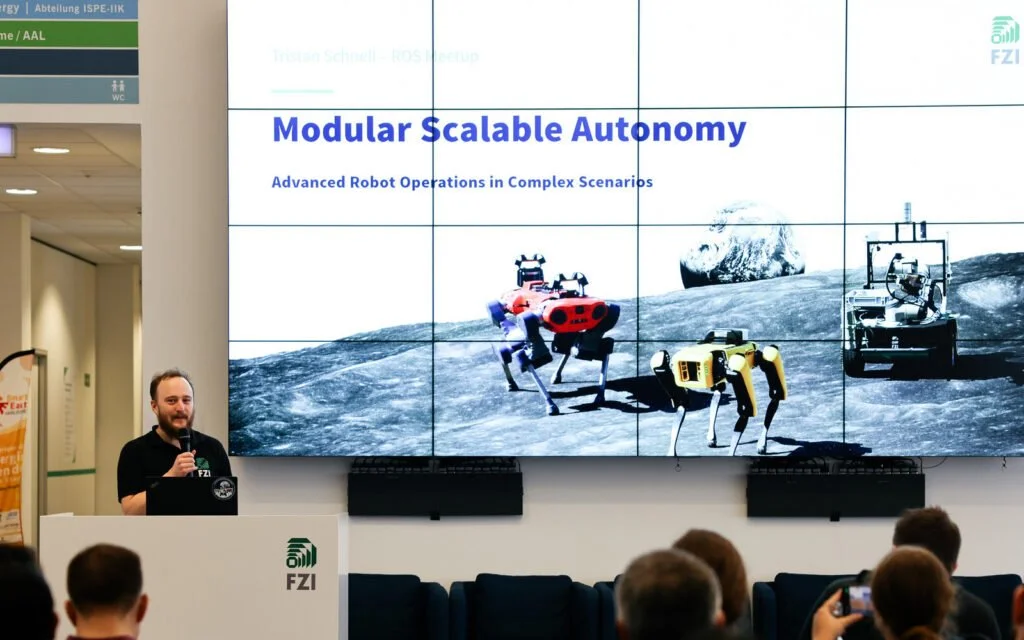

In 2013, the sales of industrial robots in North America were strong, but the diversity of robot tasking remained utterly STAGNANT. For more than 20 years, industrial robots have been limited to roughly the same set of tasks – welding, material handling and dispensing – because robots are cost-effective for repetitive and high volume tasks but are not cost-effective for lower volume mixed part production, see figures below. Yet over the same 20+ years, governments and research institutions have spent more than $1 billion on robotics research to enhance robot behaviors, such as those for acting on complex perception data, moving about on mobile platforms and collaborating with humans.

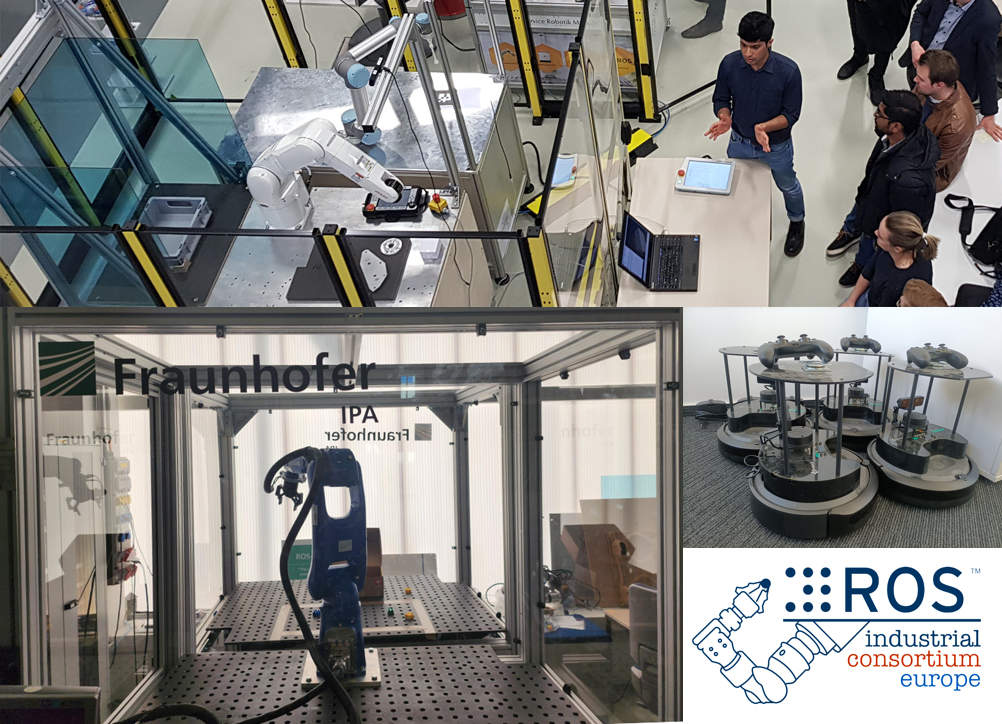

This research investment is largly languishing in labs in part because the limited software architectures of current industrial robots present a barrier to the transition of research products. As a result, it simply costs too much to apply these advanced capabilities to improve industrial productivity. Robots are flexible enough to accomplish a wide variety of automation tasks, but until the return on investment to integrate and program robots for agile processing becomes attractive, robots will continue to be deployed in only limited applications, and opportunities for greater productivity will be lost. Advances in robotics research require economical pathways to application to realize their full potential. ROS-Industrial seeks to provide this pathway.

Data for 2017 from RIA Statistics