ROS-Industrial celebrates 10 years of uniting researchers and industry to solve industrial automation challenges with open-source software

/Industrial robotics has changed dramatically from a decade ago, when a small group of researchers held the first annual meeting of the ROS-Industrial Consortium. Back then, much of the robotics research happening in university and corporate labs would languish in papers because it was difficult to replicate custom implementations using proprietary software.

Things started to change when the Robot Operating System (ROS) – an open-source software platform founded in 2007 by Willow Garage, the Stanford AI Laboratory, and Open Robotics – started reappearing in research papers. ROS helped open the door to R&D scalability across industry and academia, enabling a means to abstract robotics hardware, while also bringing a modularity and notion of abstraction and reproducibility to the robotic research space.

ROS caught the attention of a group of leading robotics companies and research institutions, including Yaskawa Motoman and Southwest Research Institute (SwRI). They teamed up with Willow Garage and founded the ROS-Industrial Consortium (ROS-I), which held its first annual meeting in 2013. On May 25 of 2023, the ROS-Industrial Consortium celebrates its 10th Anniversary.

In 2013, when ROS-Industrial held its first meeting at SwRI in San Antonio, there were 14 member organizations. Today, membership has expanded to over 85 organizations representing a broad range of industries and academic institutions.

The First ROS-I Consortium Gathering March 2013

How ROS-I Harnessed the Potential of Open-Source for Industry

The ROS-Industrial founding organizations saw the potential of open-source robotics technologies to revolutionize the manufacturing industry, and they came together to create a platform that would enable the development and deployment of these technologies in a cost-effective and efficient manner. ROS-I sought to bring more advanced computer science tools and standard path planning/motion planning libraries that were not sole propriety of the robot manufacturer. This confluence enabled investigation of a new approach to industrial robotics and a chance to set a path towards new capability that was not either only in a research lab or only available via one robot manufacturer.

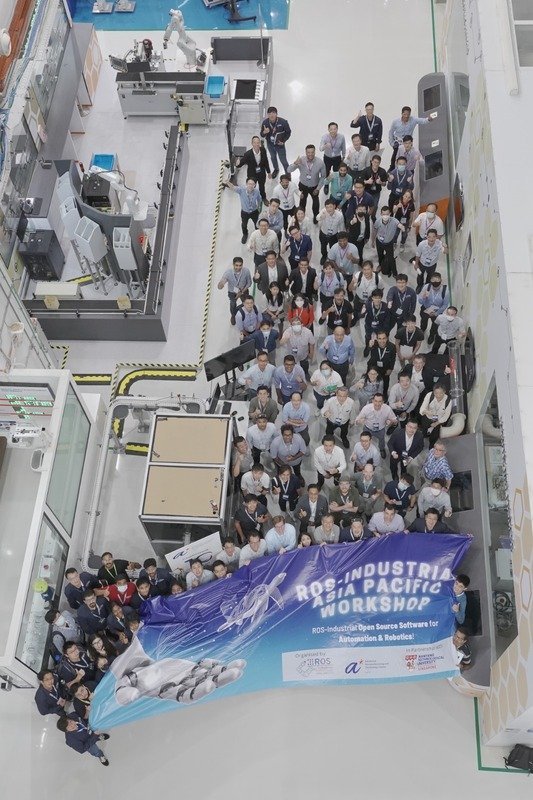

Shortly after the founding of ROS-I, that first commit by SwRI’s Shaun Edwards and Paul Hvass—with the support of SwRI’s Paul Evans and Clay Flannigan—launched the ROS-Industrial Consortium. It wasn’t long before Fraunhofer IPA in Germany and the Advanced Remanufacturing Technology Centre in Singapore launched collaborative ROS-Industrial Consortia for the European Union and Asia-Pacific regions. Their energy and ingenuity have made Consortium growth and management such a fruitful experience.

Since that time the Consortia, via collaboration and engagement with industry, have made significant progress towards the goal of accelerating the development and adoption of open-source robotics technologies for industrial applications. Some of the consortium's key accomplishments include:

- Developing a comprehensive set of software tools and libraries that enable the use of ROS for industrial applications.

- Creating a vibrant community of ROS users and developers in the industrial robotics space.

- Conducting several successful Focused Technical Projects (FTPs) that have developed new capabilities for ROS-I.

- Working with leading robotics companies and research institutions to promote the use of ROS for industrial applications.

Growing ROS-I by Improving Standardization & Expansion

Shaun and Paul have since benefitted since joining and leading Plus One Robotics while also continuing to be stewards and champions for open-source collaborative development.

Shaun provided his take on what he has seen from the start of the ROS-I Consortium and what it has enabled: “In the very beginning of ROS-I, we found ourselves defending the robustness and reliability of open-source software. Only time would demonstrate that ROS could be as robust and reliable as commercial software as it was adopted across industrial and commercial robotics. Those companies with existing robot software stacks were not able to wholesale switch to ROS. Instead, they created integrations with ROS, while mimicking features of ROS that users found compelling (e.g. rich visualizations, physics simulation, and advanced computer vision). End users with complex and dynamic robot processes found ROS was necessary in order to build advanced solution. One such example was the ROS-Industrial Scan-N-Plan project(s). Scan-N-Plan leads to deployments at end users and was later followed by several startups who productized similar technologies for welding (Path Robotics) and sanding (GreyMatter). In addition to those examples, many startups without existing software stacks, were free to start with ROS as the core of their product offering. Plus One Robotics, Fetch Robotics, Renu Robotics, and Amp Robotics are just of few of hundreds. These companies have gone on to solve valuable problems and become respectable robot companies.”

Though a lot of progress has been made, there is still a role for a consortium that fosters collaboration between the open-source community, industry, and academia. Recently it has become very clear that standardization of various interfaces, communication standards, and modeling is lacking, manifesting in numerous translation efforts and frustration when multiple protocols are required within one application. Numerous working groups are in progress to investigate these, and the ROS-I Consortium has played a role in providing input to drive an industry perspective.

Shaun took the time to add his take on what the Consortium can contribute moving forward: “The consortium speaks with a louder voice today than ever before. It should use this new standing to expand its footprint. There remain many challenges in robotics today that could be addressed by cooperative research in the vein of Scan-N-Plan and other consortium projects.”

Shaun added that, “Expansion beyond robotics should also be considered. There are more open standards and open software in industrial automation today than ever before. An advanced robot cell contains robots, PLCs, and HMIs, as well as links to the cloud for analytics and planning. All these aspects have a software component that already have or could have has open-source alternatives. Just as ROS is now firmly a part of industrial robotics, the ROS-Industrial Consortium could usher in the age of open source for the entire factory.”

The Next Decade: Building Community & Integrating AI

ROS-I is well-positioned to continue to accelerate the pace of advanced robotics for industry in the years to come. The consortium has a strong track record of success, and it has a vibrant community of users and developers who are committed to the advancement of open-source robotics technologies. In addition, ROS-I is working with leading robotics companies and research institutions to promote the use of ROS for industrial applications. ROS-Industrial seeks to enable efficient incorporation of Artificial Intelligence in its various forms, and supporting commercial entities that seek to streamline the ease of use for robotics and AI together.

The ROS-I Consortium will continue to work towards providing value not only to its members, but also to the open-source robotics community. This includes example applications, helping to make open-source robotics technologies more accessible and affordable, and it is enabling the development of new and innovative industrial capability that can improve productivity, safety, and quality.

We look forward to collaborating with the robotics community more broadly to enable more end-users to solve their complex challenges in an efficient way and provide the means to entrepreneurs to have bankable new tools for which to address the needs of their target market. At this, the 10-year anniversary of the Americas Consortium meeting where members gather to share the latest in open source for industry, we will seek pathways to continue this mission. The ROS-I Consortium has enjoyed providing the foundation and we look forward to continuing to enable the industrial robotics solutions for tomorrow.

For remote attendees live streaming of talks has been a tradition and was made available and recordings of the sessions will be available in the future.

To learn more about the Annual Meeting, visit https://rosindustrial.org/events/2023/5/ros-industrial-consortium-americas-2023-annual-meeting.

To learn more about the ROS-Industrial Consortium, visit https://rosindustrial.org.