RIC- Europe Event Recap (Part 2): ROS-Industrial Training and Conference 2016

/Note: Part 1 of the RIC-Europe Event Recap covered the ROS-Industrial training and was posted last week and can be found below.

This year’s ROS-Industrial Conference was upgraded, and held over two days with 21 talks, more than doubling last year's ten talks. Brian Gerkey from the Open Source Robotics Foundation (OSRF) and formerly of Willow Garage, where ROS was born, gave the first keynote which talked about the origins and recent and upcoming developments of ROS. He gave also an overview about the development and current status of the community and presented a variety of industrial use cases using open source software. Prof. Michael Beetz, an authority in the field of cognitive robotics, delivered the second keynote. His presentation dealt with the very important topic of digital infrastructure to empower service robots with a shared and open knowledge base, as market and technology developments foresee different robots in different environments performing different tasks. The presented platform openEase is possibly the most advanced open-source platform for a web-based knowledge service allowing for collection, storage and inspection of activity data for robot and human tasks.

Dr. Brian Gerkey opened the ROS-Industrial Conference with a keynote about the origins of ROS and recent developments.

Next up, companies ZenRobotics, PAL Robotics and next47 (a Siemens company), gave an overview about how ROS powers their business, or, in the case of next47, is seen as a common trait for up-and-coming robotics startups. After that, the participants got an overview of the most interesting technical developments going on in ROS and ROS-Industrial. Some of the works were presented recently at ROSCon and IROS in South Korea less than a month before, and we were glad to update our audience on such recent content. Part of the technical talks were:

- A presentation of the service robot Care-O-bot from Fraunhofer IPA, held by Dr. Ulrich Reiser

- A case-study on the ROS navigation stack and about deterministic timing for ROS, presented by Ingo Lütkebohle from BOSCH Corporate Research

- Matthias Gruhler from Fraunhofer IPA presented a solution to improve the navigation of industrial service robot fleets using cloud computing

- A status update about ROS 2.0 and about OPC UA was given by Matthias Keinert from University of Stuttgart The first conference day came to an end with insights into Team Delft’s technologies enabling their win of the Amazon Picking Challenge. Last but not least, Martin Hägele, head of department robot and assistive systems at Fraunhofer IPA, gave a detailed overview about ongoing developments in the worldwide robotics market. His talk covered both industrial and service robots and presented data which is collected annually by the International Federation of Robotics (IFR) and published in the “World Robotics Report.”

Prof. Michael Beetz presented the second day's keynote.

Prof. Martijn Wisse from TU Delft opened the second conference day and described a new funding strategy for ROS-Industrial focused Technical Projects set to start in 2017. Further technical talks complemented the morning session with the following content:

- Bernard Dieber from Johanneum Research talked about application-level security for ROS-based applications

- Real-Time Extension to ROS was the topic of the presentation from Jan Carstensen, working at Leibniz Universität Hannover

- A framework for quality assessment of ROS applications was presented by André Santos from INES TEC

For the ROS-Industrial consortia it is important to offer not only technical knowledge during the events but also to transfer knowledge about non-technical but highly relevant topics such as “best practices” related to open-source software and ROS. One example is the question of how to deal with safety regulations when using ROS. Theo Jacobs from Fraunhofer IPA presented some “do’s and don’ts’” with respect to safe software and to the development and application of ROS components. He gave some information about the ISO standardization committees and their procedures for establishing standards. Carsten Emde from the Open Source Automation Development Lab gave insights into open source in industrial automation, which is in fact already a reality in this business domain. He spoke about Linux and some well-known and also less well-known hurdles for its use in automation and how they are or will soon be taken, such as SIL2 certification for base components of a Linux RTOS, currently undergoing at OSADL.

Dr. Catharina Maracke from the Software Compliance Academy held the last non-technical talk about “Unterstanding License Compatibility and Compliance Risks and Processes in Free Open Source Software”. She informed, among others, about different types of licenses, their advantages and constraints and the OpenChain project that aims to address free and open source software-related friction points in the software supply chain. It was the second talk Dr. Maracke gave for the ROS-Industrial consortia, marking a continued collaboration given the interest expressed by our community in these topics. Both Fraunhofer IPA and the RIC-EU consortium are specifically concerned to keep the attention high on these matters as they often represent the reasons why open source software has still some difficulties to be widely adopted within the more conservative industrial automation environment.

Get-together during the breaks

Before the conference wrapped up, the following topics were presented in a last technical track:

- Sebastian Brunner from German Aerospace Center (DLR) spoke about RAFCON, a graphical tool for task programming

- Ontology-driven tools for robot application development were the aim of the ReApp project that was presented by Dr. Björn Kahl from Fraunhofer IPA

- Pablo Quiles Velilla ended the track with his presentation about drag&bot, an innovative and easy way for industrial robot programming

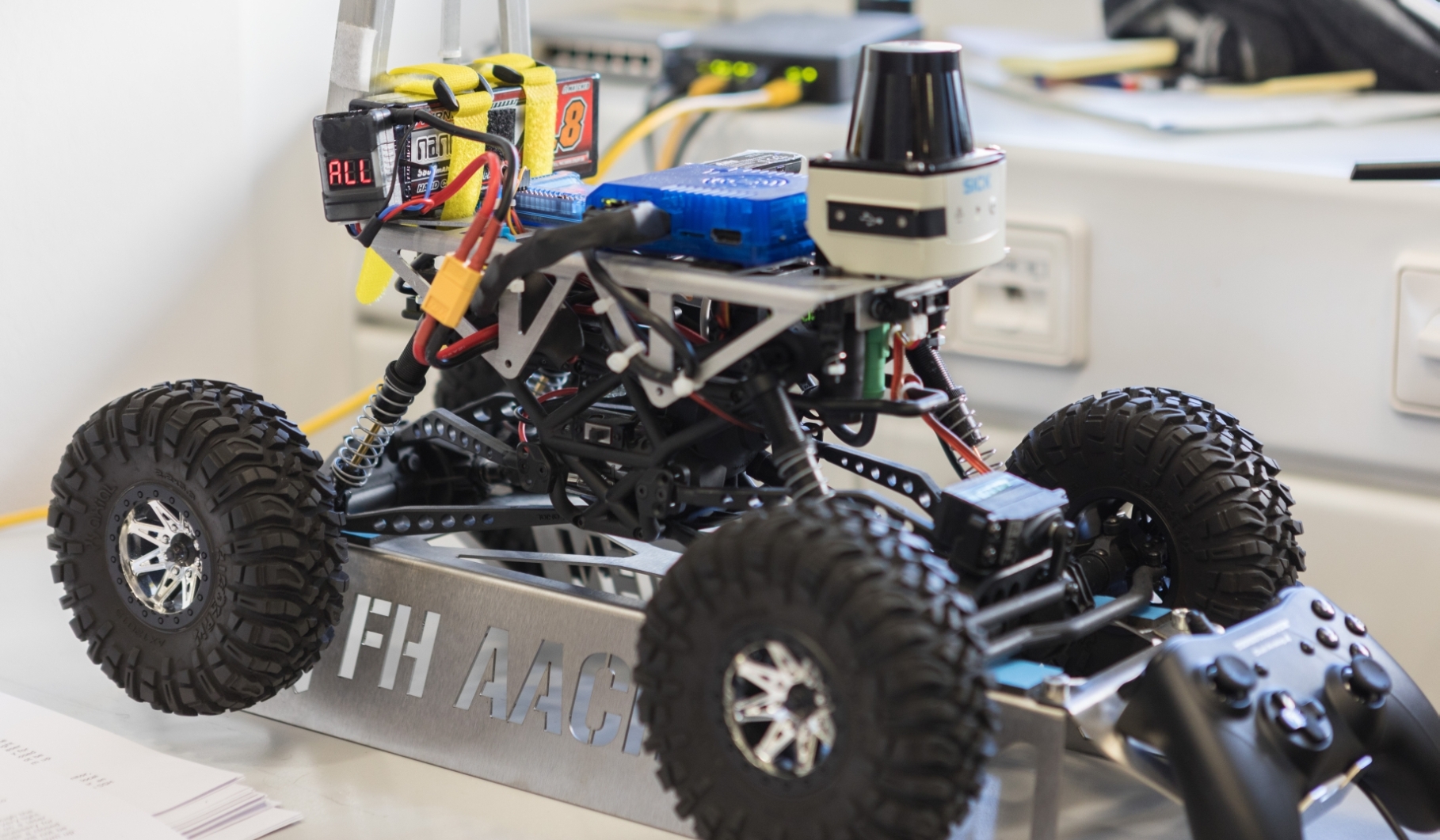

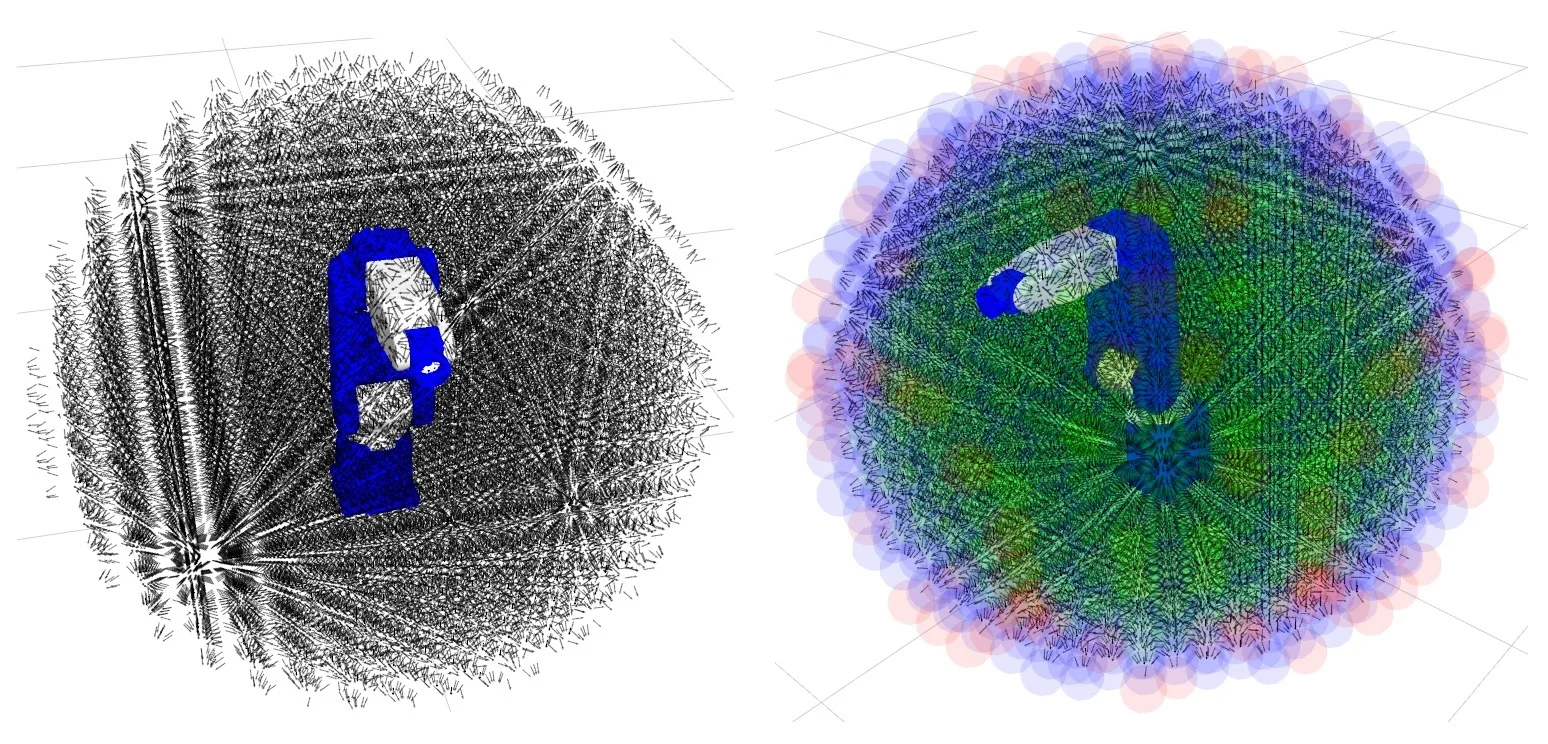

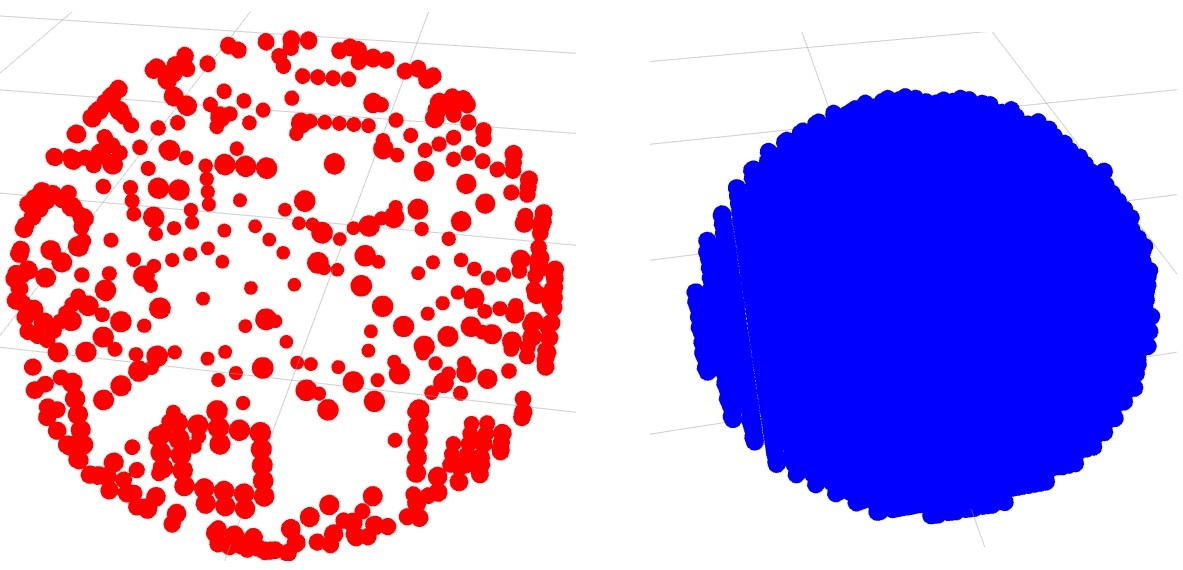

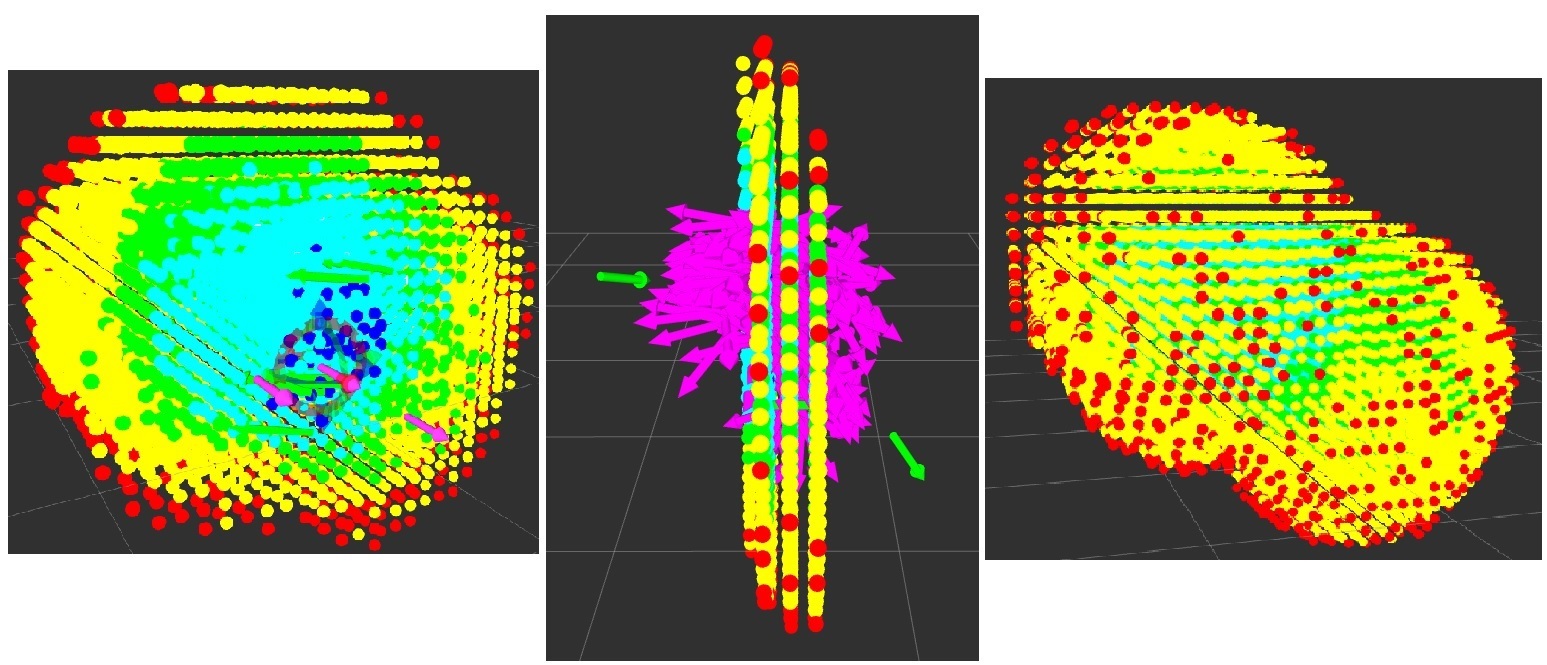

All in all, the ROS-Industrial training and conference offered extensive technical and non-technical knowledge, a variety of best practices and was also a good opportunity to get in contact with the ROS and ROS-Industrial communities and to widen the network. Thanks again to the colleagues from FH Aachen, to all speakers and of course to all participants of the event(s)!

For your reference, the detailed agenda of the whole event as well as all slides from the speakers can be found here. A picture gallery from the training as well as from the conference is available here. Please have in mind: The follow-up event in 2017 will be the ROS-Industrial Summit at RoboBusiness Europe 2017 on April 20-21 in Delft, the Netherlands. The next ROS-Industrial conference is planned for the first half of December 2017.