An Open Framework for Additive Manufacturing

/Mainstreaming Robotic Based Additive Manufacturing

Robotic additive manufacturing, sometimes called robot 3D printing, is evolving from research to applied technology with maturation of methodologies (gantry systems and robot arms) and source materials (metal powder, wire, polymer and concrete).

A conventional gantry system that layers material via a single x-y plane tool path is an established 3D printing solution for certain repeatable applications, while robotic arms can offer more complexity when layering material in multiple planes. However, to date traditional approaches for planning trajectories for 3D printing are not optimized for taking advantage of high degree of freedom (DOF) systems that include industrial manipulators.

Leveraging the advances in planning for high (DOF) robotic arm equipped solutions for complex additive manufacturing (AM) entails processes for planning and execution for both hardware and the work environment. The steps of a process are dependent upon often multiple proprietary software tools, machine vision tools, and drivers for motion planning end effectors, printer heads and media used in each 3D printing process.

ROS Additive Manufacturing

Over the years the ROS-I open source project and within the ROS-Industrial Consortium the creation of frameworks that enable new application development have become a standard approach to enable rapid extensibility from an initial developed application. After numerous conversations with end-users, other technical contributors, it seemed that there was an interest in looking at some of the capabilities within the ROS and ROS-I ecosystem to create a framework that seeks to take advantage of high Degree of Freedom systems and optimization based motion planning to bring a one stop shop in additive manufacturing planning and application.

ROS Additive Manufacturing (RAM) aims to leverage the flexibility of additive manufacturing with industrial robotic applications. While looking for an open-source ROS package to slice meshes into configurable trajectories for additive manufacturing using a Yaskawa Motoman welding robot, we have been aware of the ROS Additive Manufacturing package developed by the Institute Maupertuis in Bruz, France, and so this was used as a starting point.

The RAM package was originally built in ROS Melodic, so it was rebuilt in ROS Noetic from source. Building the application from source in Noetic was mostly straightforward. We followed the the installation instructions detailed in the Maupertuis Institute's GitLab repository. The terminal commands using pip were replaced using pip3 and all terminal commands specifying ROS Melodic were replaced with ROS Noetic. When attempting to build the package in ROS, there were clashes between Sphinx 1.7.4 and the latest version of Jinja2 (version 3.1.2 as of June 2022). An older version of Jinja2 (version 2.10.1) was installed to successfully build the package and for the software to launch.

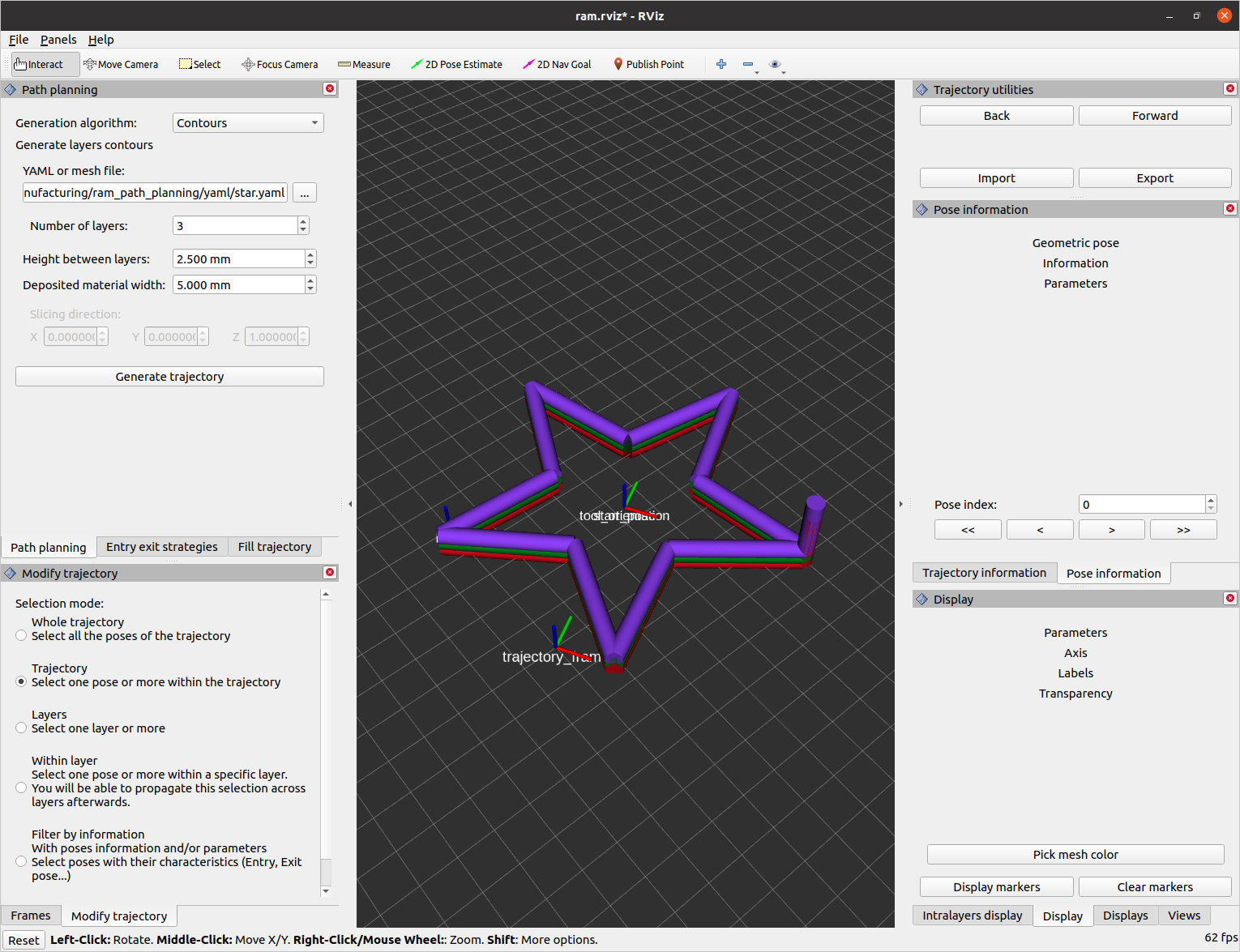

The RAM software features an RViz GUI interface that allows the user to select various trajectory generation algorithms to create a trajectory from a given mesh or YAML file. Printing parameters such as blend radius, print speed, laser power, and material feed rate can be modified for each individual layer of the print. The parameters of the entrance and exit trajectories can also be modified to have a different print speed, print angle, print length, and approach type. The output format of the exported trajectory is a ROS bag file. For our experiment, we used a Yaskawa Motoman welding robot and we needed to post-process the results to correctly interface with the robot.

Going from Plans to Robot Motion

Motion was achieved by post-processing trajectories with a customized version of the robodk post-processor. Welding parameter files were defined on the robot's teach pendant like normal. A "User Frame" (reference system) was defined at the center of the metal plate to match the ROS environment. The robot's tool was edited to match the orientation used by ROS. This allowed us to generate robot programs without having to configure the ROS environment to match the workcell. Extra lines were added in the post-processor to start/stop welding. The program files were copied via ftp onto the controller and executed natively as Linear moves.

This hybrid ROS/robot controller set up allowed us to quickly set up this demonstration. The output of the tool is a list of cartesian poses. The post-processor converted these to linear moves in the robot's native format. The robot did the work of moving in lines at a set velocity; there was no reason to do additional planning or create joint trajectories. The robodk_postprocessors package available on Github has not been maintained or updated in some time. Numerous bugs exist and these needed work arounds.

Existing ROS drivers are focused entirely on joint trajectories. A different approach that would allow streaming of robot programs would be beneficial, and this is part of future work to be proposed.

Below are two screenshots from the software for trajectories produced for a star and a rectangle with rounded corners. These shapes were included within the software as YAML files. The Contour generation algorithm was used with a 2.5 mm layer height and a 5.0 mm deposited material width for both shapes . The star shown below had three layers and the rounded rectangle had five layers. All other parameters were left to their default values.

Creation of a star shape set of tool paths via the RAM GUI.

Creation of a rounded corner rectangle within the RAM GUI.

As seen in the video below, the GUI interface provided a convenient and intuitive way to modify trajectory and print parameters. Paired with our post-processor, sending completed trajectories to the robot hardware was efficient.

Screen capture of process within RAM software. After clicking "generate trajectory", the post processor saves the output into a JBI file which is transferred to the robot via FileZilla.

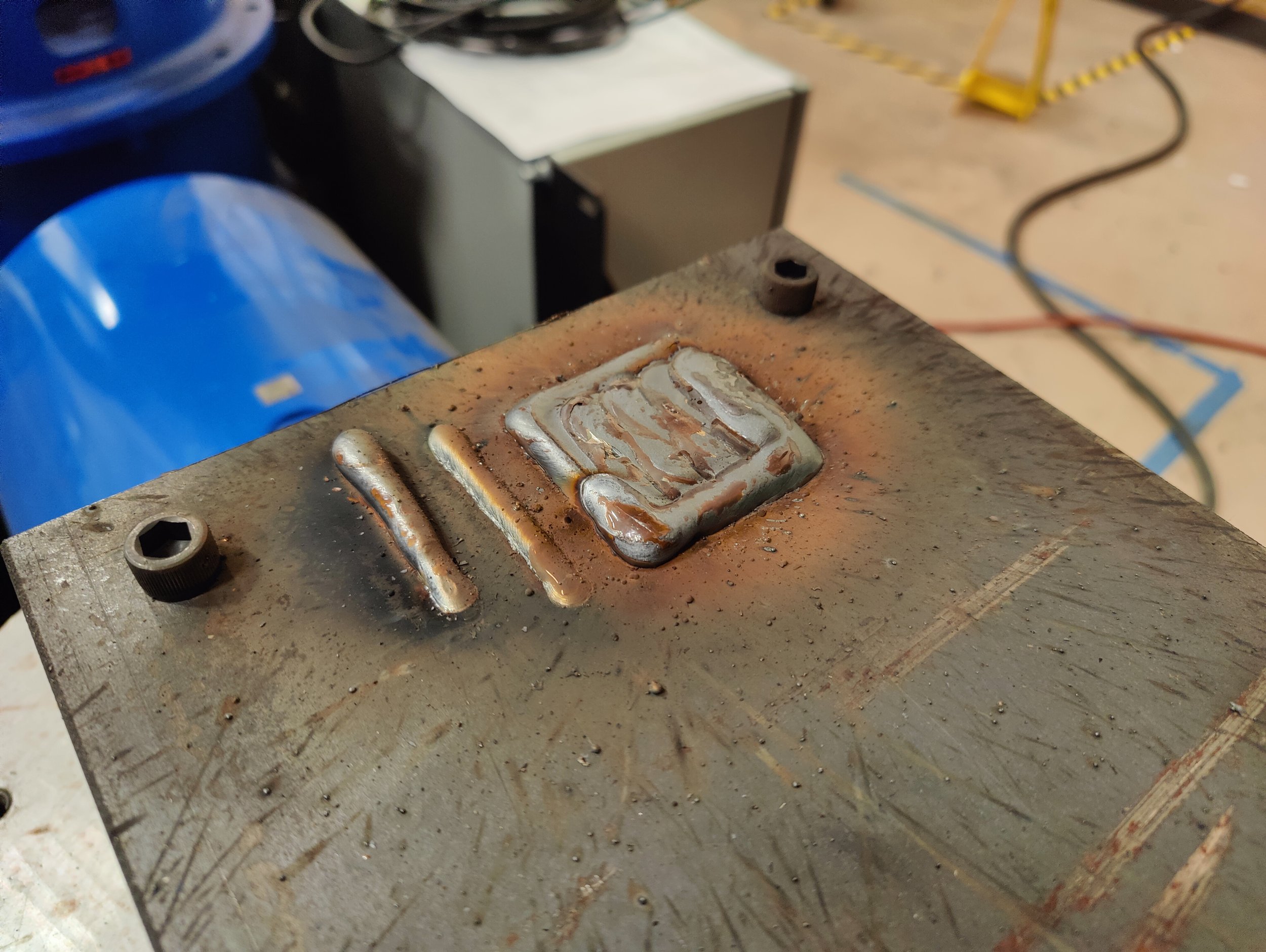

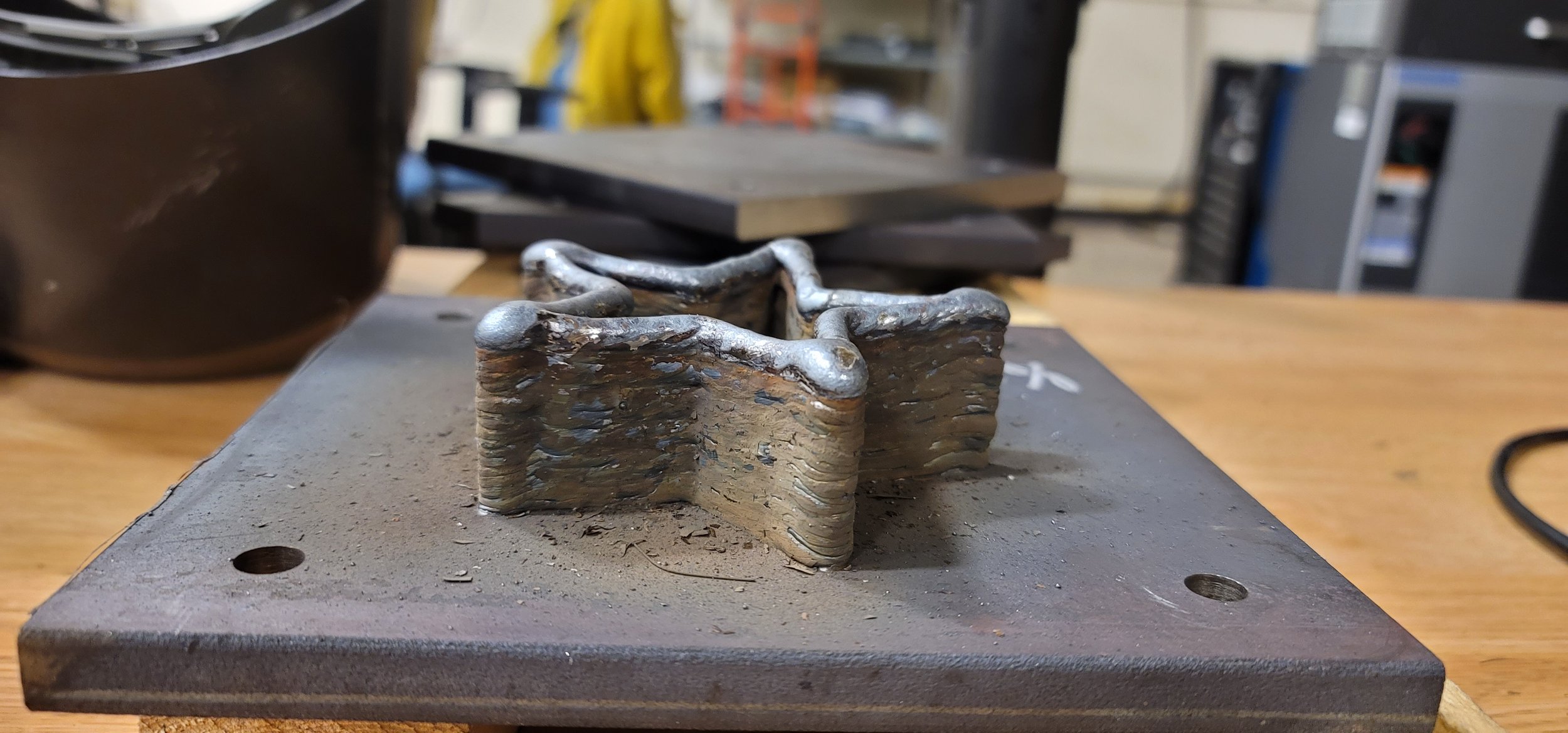

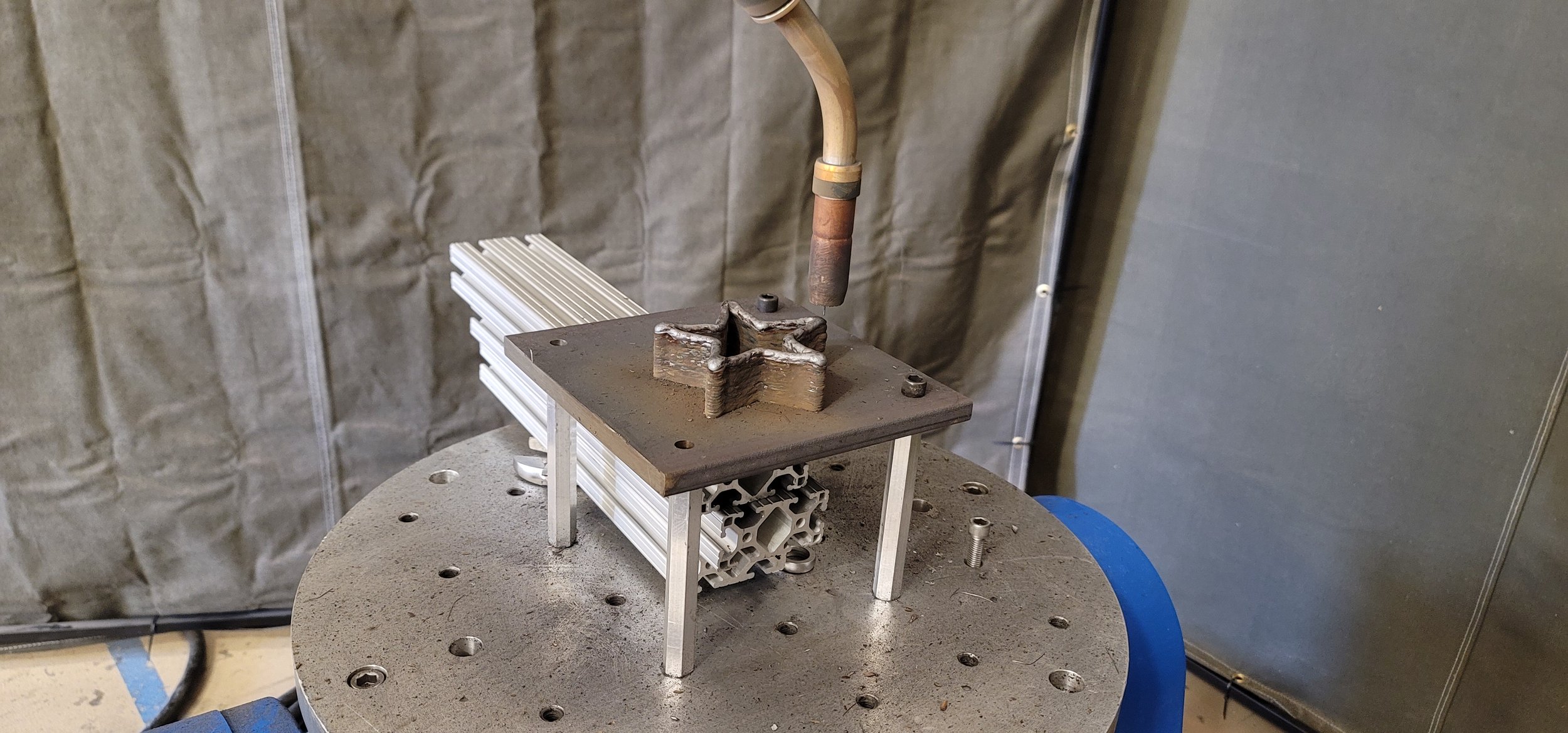

Test samples were made on a test platform provided by Yaskawa Motoman over the 2022 summer period. As can be seen in initial test samples and more complete builds, the application was able to make adjustments to motion profiles and weld settings, including more advanced waveforms such as Miller Electric’s Regulated Metal Deposition (RMD) process.

Figures Above: In-Process and completed RAM generated tool path sets executed on the Yaskawa testbed system.

To streamline the process of building the RAM package from source, the documentation should be updated to detail the process of building in ROS Noetic instead of ROS Melodic. Additionally, the documentation does not show how to interface and post-process the exported trajectories to work with robotic hardware. Although this is beyond the intended scope of the RAM software project, this would improve the utilization of this software for industrial applications. The documentation for the package is currently in French. An English translation of the documentation would would make understanding the adjustable parameters within the software easier for English speakers.

Future work seeks to incorporate the ability to fit/apply the generated tool paths fit to an arbitrarily contoured surface within the actual environment, much like is done in the various Scan-N-Plan processes for surface processing currently available within the ROS-I ecosystem, thus being able to do additional intermediate inspection and processing as the build progresses, or update build based on perception/machine vision data.

Furthermore, implementing with a new driver approach that enables more efficient tool path to trajectory streaming would improve the usability and interfacing with the hardware. Implementations of various algorithms to ensure as consistent profile/acceleration control to manage sharp transitions would also be beneficial and may be implemented through optimization-based planners such as TrajOpt. Porting to ROS 2 would also be in scope.

A ROS-Industrial Consortium Focused Technical Project proposal is in the works that seeks to address these issues and offer a complete open source framework for facilitating flexible additive manufacturing process planning and execution for high degree of freedom systems. Special thanks to Yaskawa Motoman for making available the robotic welding platform, and thanks to Doug Smith at Southwest Research Institute for working out the interaction between the RAM package and the robotic system.

Editor Note: Additional thanks to David Spielman, an intern this summer at Southwest Research Institute. This work would not have been possible without his diving into the prior RAM repository and getting everything ready relative to testing.