10th Meeting of the ROS-Industrial Consortium Americas highlights reaffirming of the mission

/On May 25 in Detroit the ROS-Industrial Consortium Americas (RICA) held the 10th iteration of the annual meeting, where Consortium members can get together, learn from each other, assess the state of the ROS-Industrial open-source project and provide feedback and engage in guided discussions, all with the intent of providing a two way interaction to understand the state and happenings relative to ROS-I and to provide their needs and areas for improvement.

A few wrinkles were included in this year’s edition. First, during the opening talk around the state of the Americas Consortium Shaun Edwards offered insights and thoughts relative to the beginnings and what we should be possibly considering looking forward.

The morning program continued with regional updates, including recent work by ROS-I Consortium EU seeking to instantiate a ROS 2 reference work cell, and highlighted recent contributions and plans to realize their vision. ROS-I Consortium AP shared their recent efforts to realize system level capabilities stemming from their extensive work around the interoperability framework Open RMF.

Kat Scott of Intrinsic shared the latest features included in the recent Iron Irwini ROS 2 release which happened only days before. A number of features highlighted include inclusion of REP-2012 Service Introspection, which is sort of a ‘ROS debug mode’ for understanding service calls and their results. Also, pre and post parameter callback, to enable parameter lists on the fly, and external logger configuration to enable only one node in verbose mode if you choose, as well as improvements in launch, rclcpp, rcl, and CLI.

Dave Coleman of PickNik shared the latest developments around MoveIt Studio and their recent efforts in support of SpaceROS with some key highlights that drive relevancy for industry, such as code quality and reliability.

To wrap up the morning session David Poweleit of the Steel Founders’ Society of America (SFSA) shared their recent initiative to sponsor a collaboration project across a diverse team including Yaskawa Motoman, PushCorp, Iowa State University, Southwest Research Institute, EWI, and ARIS Technology. The intent is to build on prior Scan-N-Plan collaborative efforts, referred to as Robotic Blending which had been through 4 prior milestones, to realize a prototype job shop system to enable high mix low-lot foundry finishing. This served as a lead-in for the broader goal and mission around the SFSA and their members relative to enabling funded research to get into foundries more efficiently.

From here Keynote speaker Shane Whitaker, Applications Engineer at Lockheed Martin, shared how and why their team has chosen to leverage ROS and open source in their pursuit of advanced capability. The value proposition for the nature of the operations is around the realization of operational agility for their environments and the nature of the tasks they need to get done to produce the products in their factories. The number of processes of interest and developed, leveraging open source, were broad, and it was inspiring to understand that these developments are making a difference on the floors of Lockheed Martin factories.

Shane Whitaker from Lockheed Martin shares their Agile Automation journey and how ROS has made an impact for their operations

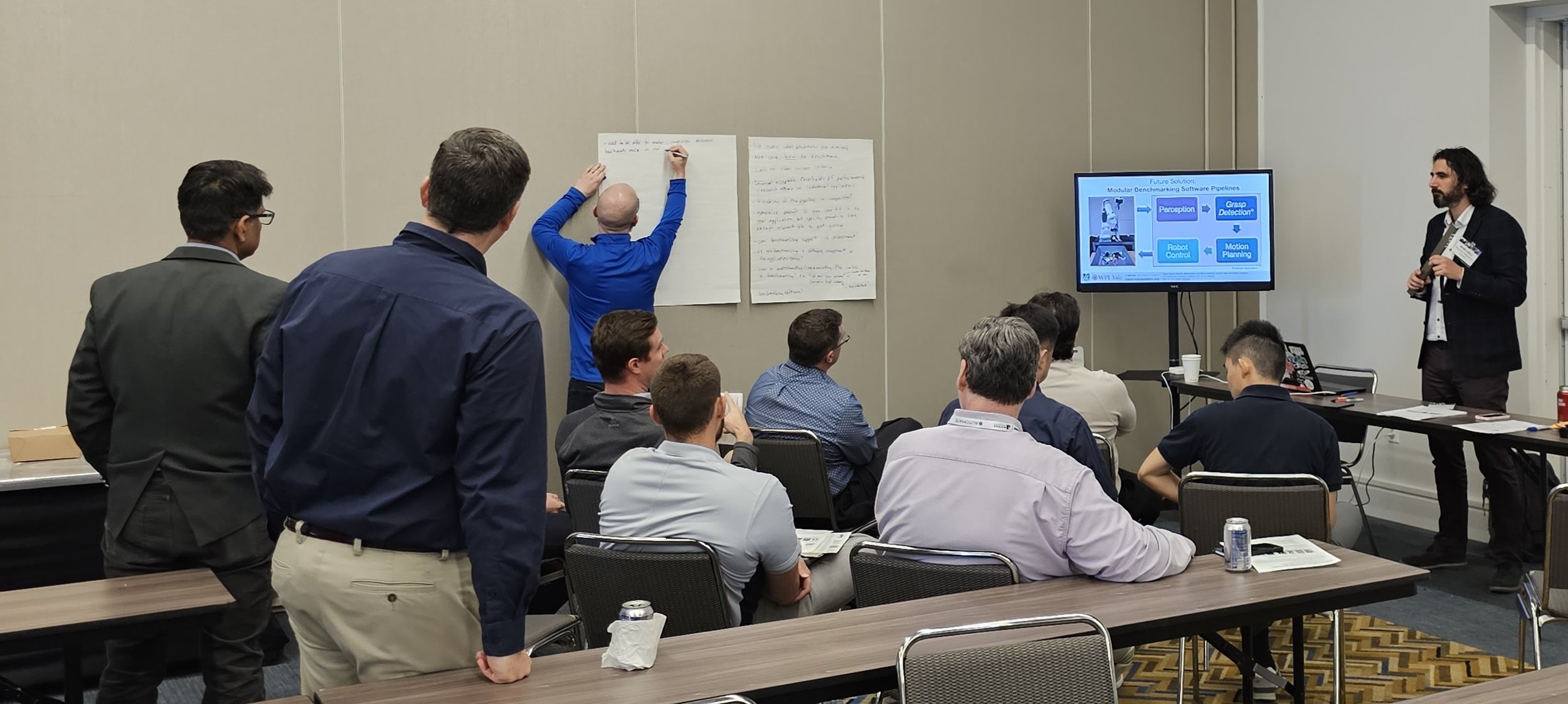

New for this iteration of the annual meeting was offering externally guided workshop time. Per past annual meetings we spend time discussing what is within ROS-I, seek to drive conversations to understand what those that are looking for capability need, both with regards to capabilities and resources to enable their success. A lot of feedback was gathered, and some really interesting insights were shared. A more formal report on feedback will be coming soon.

The additional workshops were led by David Poweleit of SFSA and Adam Norton of the Nerve Center at University of Massachusetts Lowell. David led a dialog, largely centered around the SFSA members that were in attendance, but also solicited great responses from other general industry members that have similar challenges as the foundry industry. Technology developers also engaged, asking about requirements, the desired types of capabilities, and means to operate.

Adam Norton along with colleague Berk Calli of Worcester Polytechnic University led a conversation around their National Science Foundation funded work on Pathways to Enable Open-Source Ecosystems starting with Open-Source Robotic Manipulation and Benchmarking: Current Gaps and Future Solutions. The scope was broad as it covered open-source assets, such as software, designs of physical robotic components and systems, datasets that support AI/ML, and instructional elements that enable benchmarking of various components. The goal is to drive a discussion on what is missing and how can we better assess and continue to grow leverageable open-source assets and compare them to sustain a future where open-source plays a key role in innovative development. You can learn more about this initiative via this handout and the presentation shared at the workshop.

Diving into the afternoon Bharath Rao, Senior Research Lead at Spirit AeroSystems, covered their vision for sustained deployment of advanced systems and solutions for entire value stream monitor and control across many assets, some human driven, others if not autonomous a future where they are. Bharath laid out a compelling vision for how a manufacturing entity may leverage open-source to realize a vision over incremental capability introduction that grows with testing, validation and improvement.

Dr. Eugen Solowjow, Head of Research at Siemens Berkeley, shared the recent work within Siemens to enable AI for robotics and how they are delivering products that enable AI solutions to run on and interoperate with traditional industrial hardware, such as PLCs.

The latter part of the afternoon included the latest in improved motion profile accuracy at high speeds for complex 3D curves presented by Dr. John Wen of Rensselaer Polytechnic Institute. This work has been really exciting for those that want to leverage autonomous motion planning but struggle with how the actual manipulator turns the sent trajectories into real motion. The two-step process includes a redundancy resolution algorithm that filters and adjusts the input target tool path and then leverages a reinforcement learning approach to further tune the manipulator that may be done on hardware via a handful of dry runs or in the OEM simulation engine if it accurately represents the physics. These tools have been provided in the RPI open-source repositories and have been developed in the course of an ARM Institute project.

Wrapping up the day, Joseph Giampappa of the ARM Institute provided an update on the latest initiatives within the ARM Institute, and the day concluded with Ted Miller of Yaskawa Motoman announcing the official release of MotoROS2. This is the latest in ROS 2 support in the industrial manipulator domain and the first where the ROS 2 node actually runs on the robot controller.

Looking back, it was a great week in Detroit and a great day spent with all the organizations, collaborators and individual developers seeking to make open-source for industry a leverageable resource for innovation in industrial settings. The continued development and latest work taking place both in the open-source and within the organizations that are leveraging open-source and making contributions, are building on the legacy and enabling new players to deliver novel new solutions. This brick-by-brick approach enables broader opportunities for innovation while enabling educational resources for future roboticists.

ROS-I Consortium americas Annual Meeting attendees gather for a group shot to wrap up the event

Thanks to all those that have made ROS-Industrial a successful collaboration, and thanks to all of those that have supported the ROS-Industrial Consortium around the globe. Through collaboration and a framework that enables continuous progress, open-source for industry can continue to make an impact for the advanced manufacturing needs of tomorrow.

All the talks described above are in a playlist at the ROS-Industrial YouTube channel. If you are interested in getting involved in the ROS-Industrial open-source project, you can learn more here. If you are interested in the benefits of the ROS-Industrial Consortium, you can check out the membership details here and feel free to reach out!