What Took Place at the ROS-I Consortium Americas 2019 Annual Meeting

/After the Automate 2019 Exhibition and Conference the ROS-Industrial Consortium Americas held their 2019 Annual Meeting in Chicago, Illinois, on April 12. This is the primary face-to-face opportunity for the Americas membership, whom have expressed interest in leveraging ROS and additional open-source solutions, in industrial and manufacturing applications. This event has proven to be a great opportunity to engage with end-users, OEMs, solution providers and researchers on open source, interoperable, agile software capabilities.

As has been the custom when held in Chicago following Automate, the meeting was confined to a single day. This led to a packed agenda with attendance at a record for the co-located variant of the Americas Annual Meeting. As was stated in this year’s program, “As evidenced by the activity and the sheer number of entrants into the order fulfillment/warehouse and logistics space, this area has proven that ROS-based solutions can survive and even thrive in manufacturing environments where uptime and reliability of performance are critical.” The day that followed demonstrated that there is both interesting and tangible activity as well as plenty of opportunity to continue to innovate while leveraging open source to step-change how innovation in industrial automation takes place.

The day kicked off with strategic and technical updates from each ROS-Industrial region. The Americas Consortium reviewed their “roadmapping” effort with an emphasis on managing the transition from ROS to ROS2. Levi Armstrong shared technical developments, including a summary of Industrial YAK, a TSDF-based reconstruction package, and an approach to enable the ability for ROS-I to support ROS and ROS2 applications moving forward.

Full House for 2019 ROS-I Americas Annual Meeting

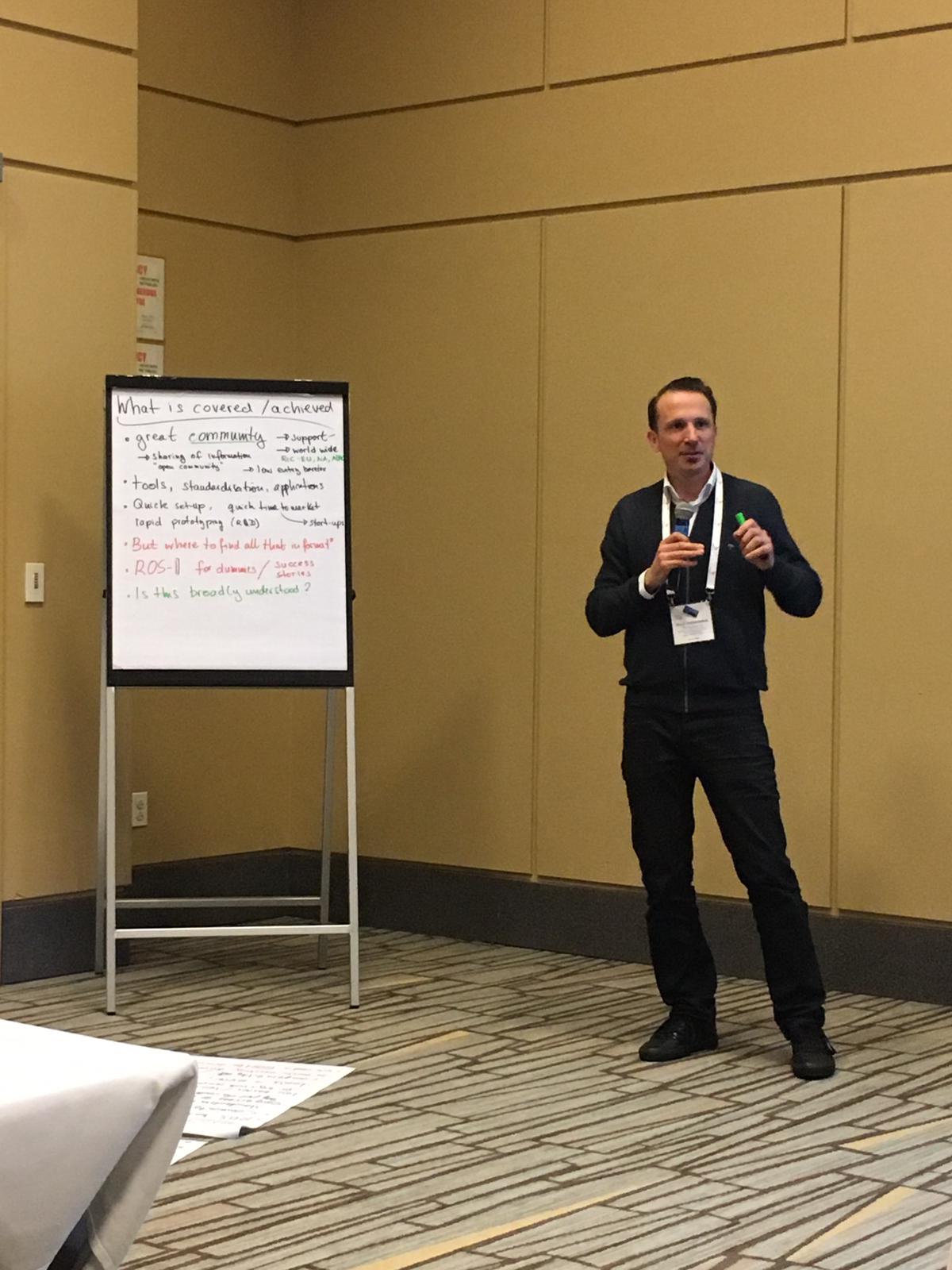

The EU Consortium was able to highlight evolutions for the progress of open source and ROS in industry. This followed with a ROSin program update for the Americas audience. Asia-Pacific discussed some of his team’s work around Dynamic Grasping and a Singapore-funded initiative “ROS-based National Healthcare Project” that will be open-source, expanding application of ROS in an IoT use case.

A follow-up roadmapping workshop was held, seeking to collect feedback on technical needs and gaps, programmatic gaps, what is working, and what application areas are the greatest needs. The intent is to gather feedback to continue to ensure a solid roadmap, both for the transition and/or incorporation of ROS2 and other open-source capabilities, and ensuring that FTP topics are aligned with the demands of the membership and Industrial community.

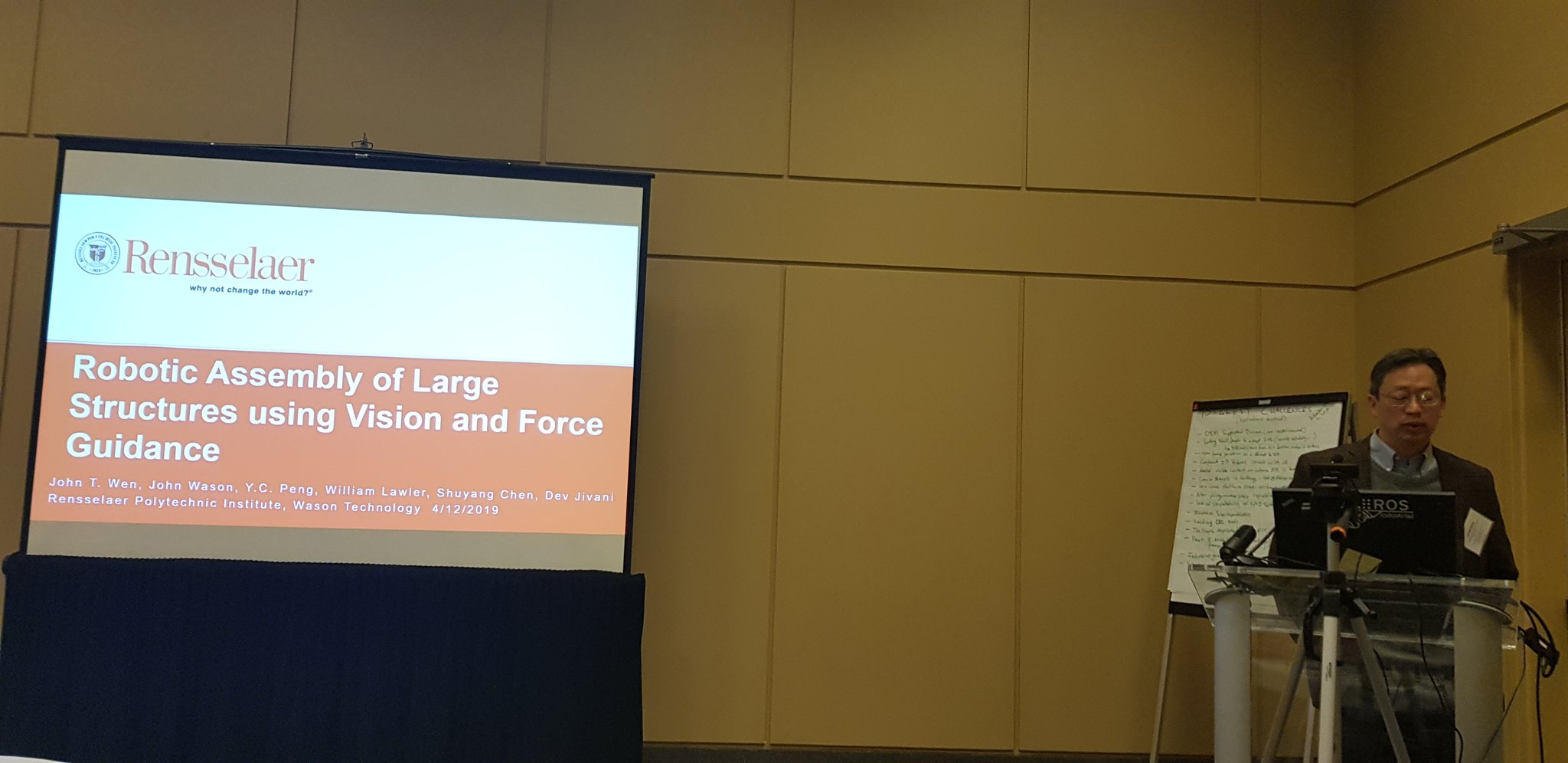

This followed with an overview by Dr. John Wen of Rensselaer Polytechnic Institute on Robotic Assembly of Large Structures using Vision and Force Guidance. This work was a product of the ARM Institute’s Quick Start Technology Projects. The work shows the ability to realize millimeter assembly performance leveraging tools such as ABB’s External Guided Motion Interface along with visual servoing techniques.

Dr. Eugen Solowjow presented compelling work that sought to leverage Artificial Intelligence techniques to enable robot learning for path planning to perform assembly and placement tasks. This highlighted a gap in the ROS ecosystem relative to advanced AI frameworks and the inability of ROS to interoperate with these tools at this time.

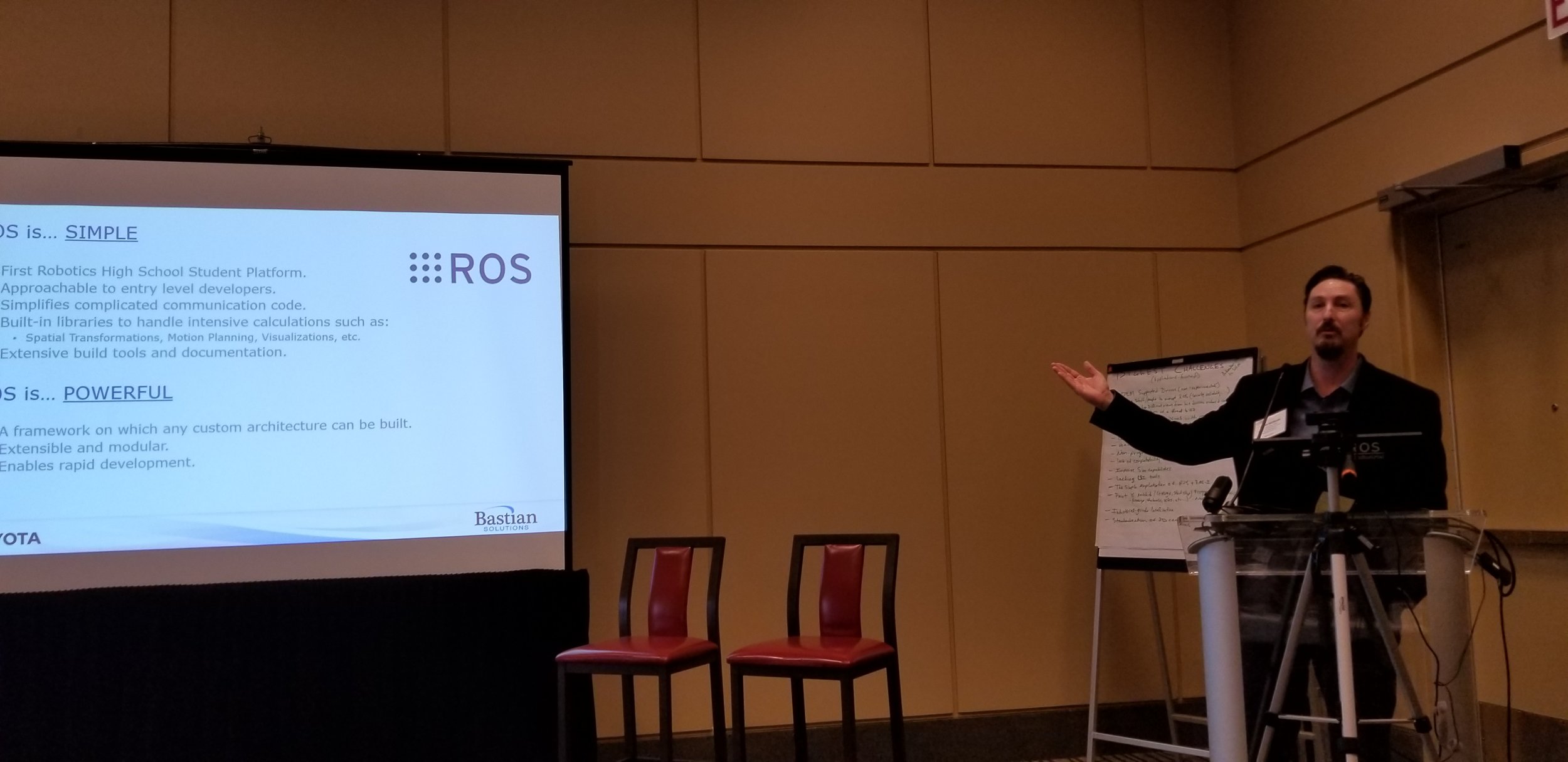

We were then able to welcome keynote speaker Chris Morgan, chief innovation officer of Bastian Solutions, a Toyota Advanced Logistics company. He talked about how ROS enables a one-stop shop, if you will, to enable his team to innovate rapidly to come up with the next generation of warehouse automation technologies, including mobile robotics.

Ahead of the presentation portion for the afternoon, members presented and discussed Focused Technical Project (FTP) topics. This was followed by, Fred Proctor, National Institute of Standards and Technology (NIST), Group Leader of the Networked Control Systems Group sharing with the membership developments of techniques to assess robotic system performance relative to agility, and how there is a need to enable common language as robotics capabilities advance.

Vincent Tam of Microsoft’s Windows 10 IoT team presented updates relative to Microsoft’s Kinect and the tools to enable rich application development within the Windows and Auzure ecosystems.

A panel session titled “Is ROS2 Ready for the Factory Floor?” featured Chris Lalancette of Open Robotics, Dave Coleman of PickNik and MoveIt!, Matthew Hansen of Intel, and Jerry Towler of Southwest Research Institute’s Unmanned Ground Systems Group. They discussed ROS2 experiences and some of the challenges related to its broader adoption. The discussion, moderated by SwRI and ROS-I Americas tech lead Levi Armstrong, covered university uptake of ROS2 versus ROS, why industry is pulling for ROS2 and techniques for managing this transition period, as well as guidance or tips for leveraging ROS2 when starting from scratch or if you have an existing ROS code base. The audience exhibited passion while engaging in a lively conversation that added additional context to publications or word of mouth that have framed the state of ROS2 at this point.

ROS2 Panel on Readiness for the Factory Floor

The afternoon session concluded with an introduction by Tormach CEO Daniel Rogge on their work seeking to create a ROS package for the MachineKit component HAL, the Hardware Abstraction Layer, and described what this enables. This was followed by an OEM partnership highlight that served as an example of how Yaskawa enables advanced applications by supporting up-and-coming companies with compelling new ideas; in this case, Path Robotics spoke to the membership about their vision to change how robotic arc welding is deployed for small and medium manufacturers.

The day concluded with a presentation by Dr. Mitch Pryor and the work his team at the University of Texas at Austin Nuclear Robotics Group is doing to reduce operator burden and enabling richer leverage of advanced robotics that in certain cases lead to improved worker satisfaction and overall performance improvements compared to legacy tele operation applications.

It was a full day, after a full week, but we were thankful to the attendees, and all the members who came in person and engaged via the online streaming of the event. For members, all the presentations and the recordings of the presentations and panel will be made available via the member portal. Moving forward, the ROS-Industrial Consortia globally will seek to bring back the ROS-Industrial Community meeting, a quarterly update that was a more meaningful means to maintain engagement throughout the year across the regional Consortia. The hope here is to optimize programs such as ROSin, and to provide two-way communication channels for these projects/funding sources beyond their core audience, and to enable a checkpoint to ensure that strategically ROS-Industrial as a project is synchronized and each dollar that is put towards ROS-Industrial is most effectively utilized.

Global ROS-I Team from Left to Right - Levi Armstrong (SwRI), Erik Unemyr (ROS-I AP), Chris Bang (SwRI), Thilo Zimmerman (Fraunhofer IPA), Paul Evans (SwRI), Mirko Bordignon (Fraunhofer IPA), and Matt Robinson (SwRI)

We look forward to continued action that stems from this event, and all the events we have in the coming months. ROS-Industrial Asia-Pacific will have its annual workshop June 18-20 in Singapore, and World ROS-I Day, our annual “house cleaning” on the code itself, is tentatively schedule for the last week in June.

Thanks to all those that engaged with the ROS-Industrial Global team the entire week, including the Annual Meeting. Without your support, open-source for industry would just be a tag line, but as evidenced by the progress to date, it is a reality.